1 Unmatched Performance of PTFE Skived Sheets

PTFE skived sheets have emerged as the premier choice for industrial applications requiring superior chemical resistance, thermal stability, and low friction. These precision-engineered sheets deliver exceptional performance where traditional materials fall short.

2 Key Properties That Set PTFE Apart

2.1 Superior Chemical Resistance

- Withstands aggressive acids, alkalis, and solvents

- Ideal for chemical processing, oil & gas, and semiconductor industries

- Prevents material degradation in corrosive environments

2.2 Extreme Temperature Tolerance

- Stable performance from -200°C to +260°C (-328°F to +500°F)

- Maintains structural integrity in cryogenic and high-heat applications

2.3 Lowest Friction Coefficient

- Reduces wear in bearings, seals, and sliding components

- Improves energy efficiency in mechanical systems

2.4 Excellent Electrical Insulation

- High dielectric strength for sensitive electronic applications

- Prevents current leakage in high-voltage environments

3 Precision Manufacturing Process

PTFE skived sheets are produced through an exacting process:

- High-purity PTFE resin compression molding

- Precision skiving to achieve uniform thickness (±0.02mm tolerance)

- Strict quality control ensuring defect-free surfaces

4 Critical Industrial Applications

4.1 Chemical Processing

- Lining for reactors and storage tanks

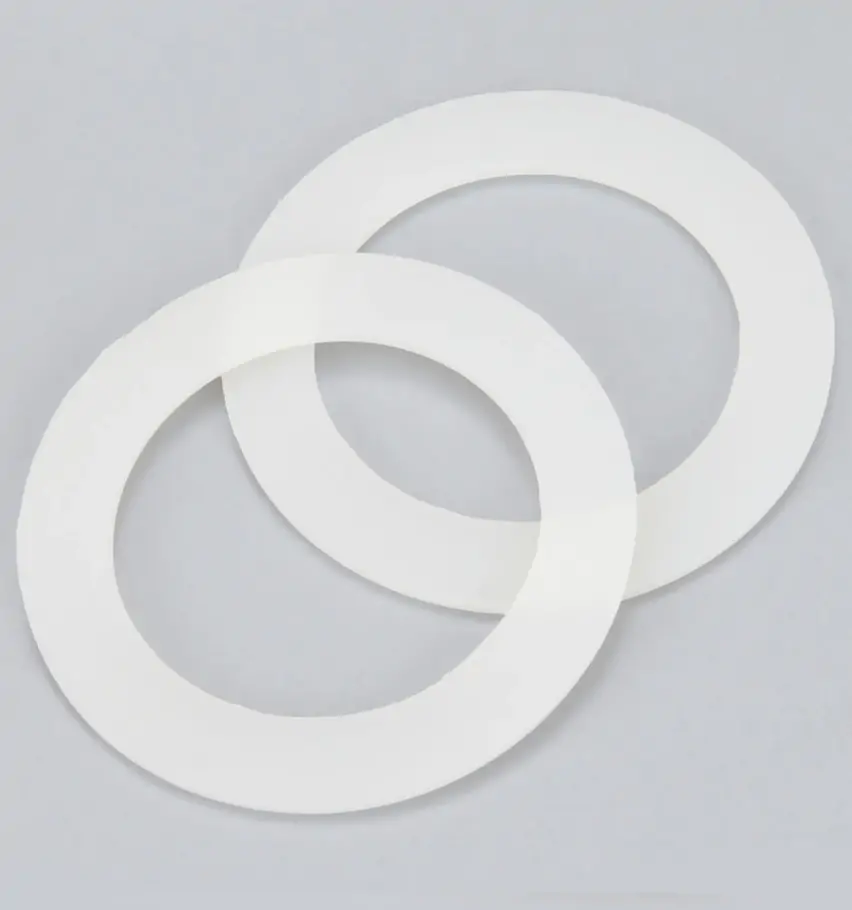

- Gaskets and seals for corrosive fluid handling

4.2 Food & Pharmaceutical

- FDA-compliant non-stick surfaces

- Cleanroom-compatible material for sterile environments

4.3 Electrical Engineering

- Insulating barriers for high-voltage equipment

- PCB manufacturing components

4.4 Mechanical Components

- Low-friction bearings and bushings

- Wear pads for heavy machinery

5 Advantages Over Alternative Materials

| Feature | PTFE Skived Sheets | Rubber | Metal | Other Plastics |

|---|---|---|---|---|

| Chemical Resistance | ★★★★★ | ★★☆☆☆ | ★★★☆☆ | ★★★☆☆ |

| Temperature Range | -200°C to +260°C | -40°C to +120°C | Varies | -50°C to +150°C |

| Friction Coefficient | 0.04-0.1 | 0.5-1.0 | 0.3-0.6 | 0.2-0.5 |

| Maintenance Needs | Very Low | High | Medium | Medium |

6 Cost-Benefit Analysis

While initial costs may be higher, PTFE skived sheets offer:

- 5-10x longer service life than alternatives

- Reduced downtime and maintenance costs

- Improved process efficiency

7 Installation & Maintenance Tips

- Surface preparation: Clean with isopropyl alcohol

- Machining: Use sharp carbide tools for clean cuts

- Storage: Keep in dry, room-temperature environment

8 Industry Case Studies

- Chemical plant: Reduced gasket replacements by 80%

- Food processor: Increased production line speed by 15%

- Power plant: Eliminated insulation failures in transformers

9 Future Developments

- Nano-enhanced PTFE for improved wear resistance

- Conductive variants for static control

- Sustainable manufacturing processes

10 Technical FAQ

Q: How thin can PTFE skived sheets be manufactured?

A: Standard range 0.1mm to 10mm, with specialty production down to 0.05mm

Q: Are colored PTFE sheets available?

A: Yes, FDA-approved pigments can be added for identification

Q: What’s the lead time for custom sizes?

A: Typically 2-4 weeks depending on specifications

Q: Can PTFE sheets be bonded to other materials?

A: Special surface treatments enable bonding to metals and composites

11 Why Choose Our PTFE Skived Sheets?

- ISO 9001 certified manufacturing

- Custom formulations available

- Global logistics support

- Technical consultation services

This comprehensive guide demonstrates why PTFE skived sheets are the smart choice for engineers and procurement specialists seeking reliable, high-performance material solutions. Their unique combination of properties delivers unmatched value across multiple industries.