1 Introduction to Advanced EPTFE-Graphite Composites

Modern industrial operations demand sealing materials that combine exceptional chemical resistance with thermal stability. Expanded PTFE infused with high-purity graphite represents a breakthrough in packing technology, delivering unmatched performance in extreme operating conditions.

2 Material Composition & Key Characteristics

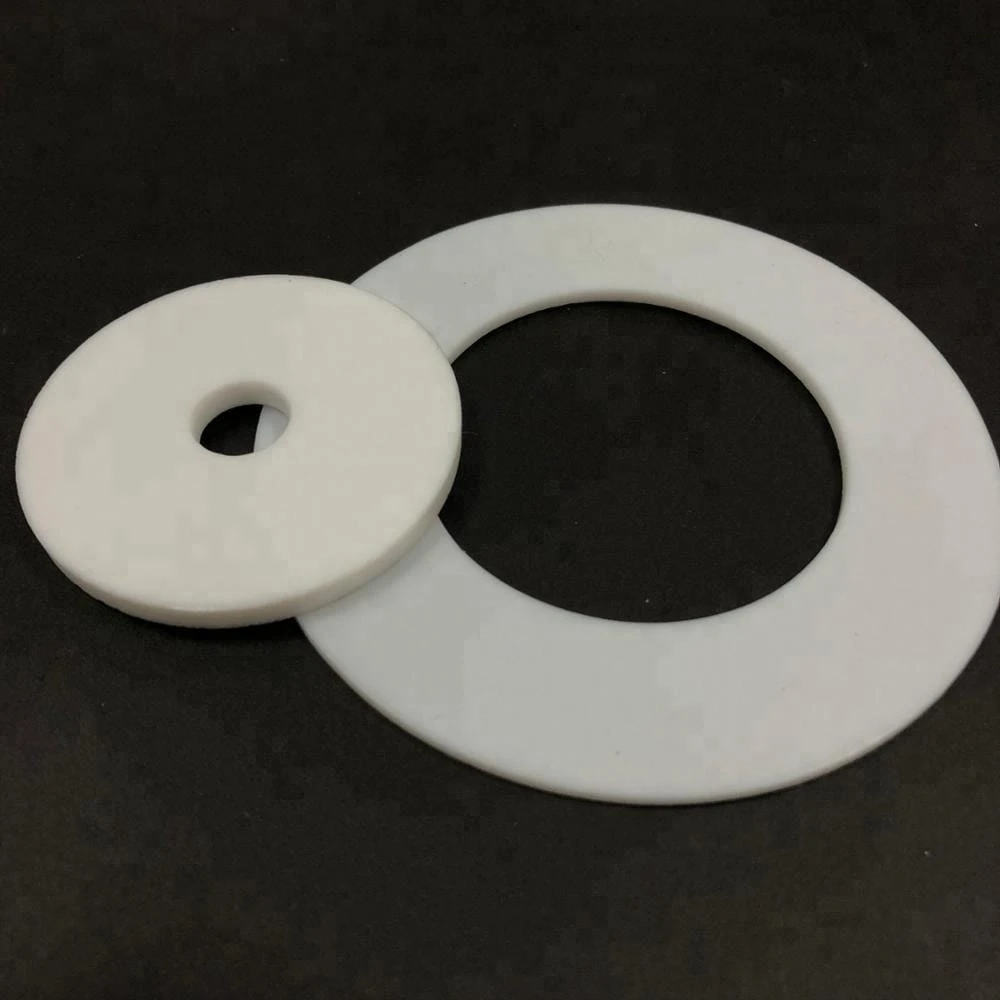

2.1 Expanded PTFE Matrix

- Microporous structure allows superior conformability

- Maintains PTFE’s legendary chemical inertness

- Flexible yet durable fiber network

2.2 High-Performance Graphite Additive

- Natural lubricity reduces friction coefficients

- Enhances thermal conductivity by 300%

- Improves compression recovery characteristics

3 Technical Advantages for Industrial Applications

3.1 Extreme Temperature Performance

- Stable from cryogenic (-200°C) to high heat (+280°C)

- Graphite prevents thermal degradation

- Ideal for metallurgical furnaces and steam systems

3.2 Chemical Resistance Profile

- Withstands concentrated acids (up to 98% H₂SO₄)

- Resists strong alkalis (50% NaOH solutions)

- Impervious to organic solvents

3.3 Mechanical Durability

- 40% lower wear rate vs standard PTFE packing

- Maintains seal integrity under 200+ bar pressure

- Excellent creep resistance

4 Industry-Specific Applications

4.1 Metallurgical Processing

- Sealing solution for:

✓ Smelting furnace components

✓ Continuous casting equipment

✓ High-temperature valves

4.2 Mineral Extraction

- Pump packing for:

✓ Slurry transfer systems

✓ Acid leaching circuits

✓ High-pressure filtration

4.3 Energy Generation

- Critical applications in:

✓ Steam turbine gland packing

✓ Boiler feed pumps

✓ Geothermal systems

5 Performance Comparison

| Parameter | EPTFE+Graphite | Standard PTFE | Asbestos Packing |

|---|---|---|---|

| Max Temperature | 280°C | 260°C | 500°C |

| Chemical Resistance | ★★★★★ | ★★★★★ | ★★★☆☆ |

| Friction Coefficient | 0.08 | 0.12 | 0.15 |

| Service Life | 18-24 months | 12-15 months | 6-9 months |

6 Installation Best Practices

- Surface Preparation: Clean shafts to Ra 0.8μm finish

- Packing Technique: Use staggered joint configuration

- Break-in Procedure: Gradual pressure increase over 48 hours

- Maintenance Schedule: Quarterly compression adjustment

7 Cost-Benefit Analysis

- Initial Cost: 20-30% higher than conventional packing

- Operational Savings:

✓ 60% longer service intervals

✓ 45% reduction in downtime

✓ 30% lower energy consumption

8 Emerging Applications

- Hydrogen energy systems

- Carbon capture equipment

- Advanced nuclear reactors

9 Technical FAQ

Q: How does graphite content affect performance?

A: 15-25% graphite optimizes lubricity while maintaining structural integrity

Q: Can it replace braided packing?

A: Yes, with superior performance in dynamic sealing applications

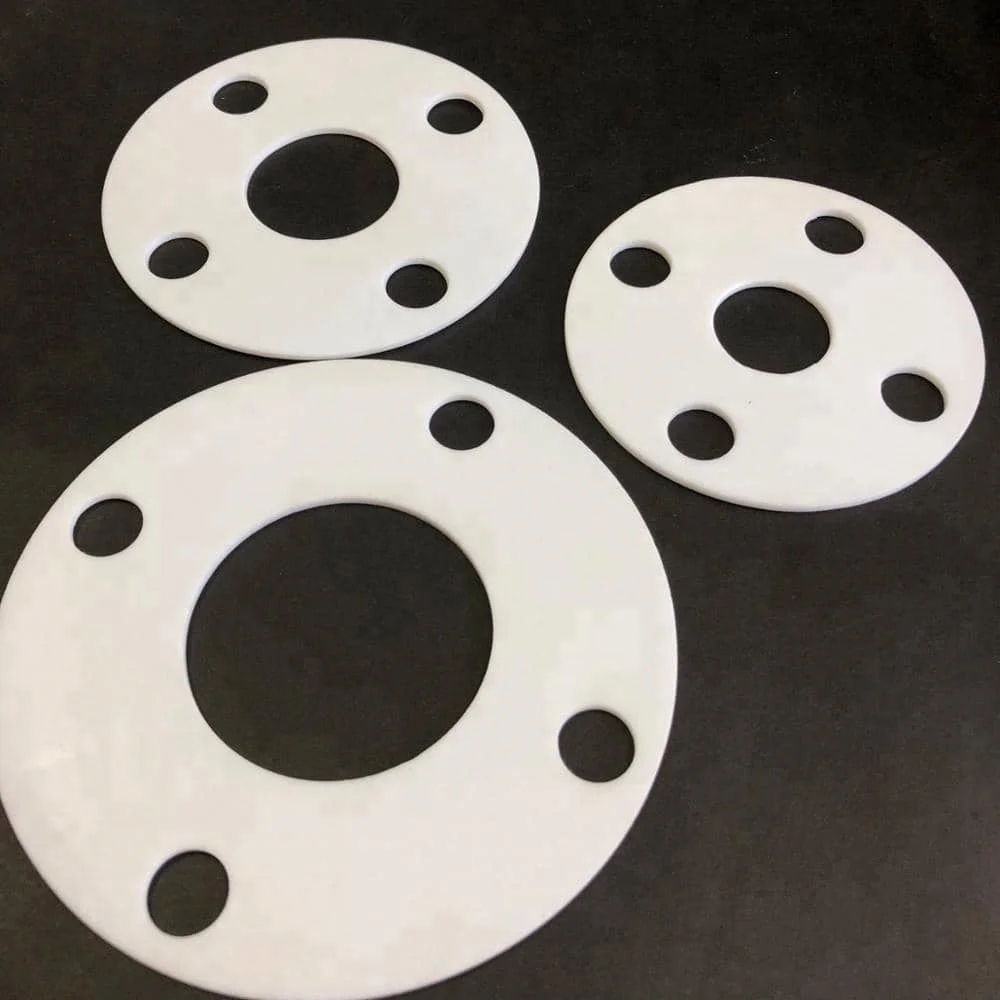

Q: Is special tooling required for installation?

A: Standard packing tools work, but laser-cut rings available for precision fits

Q: What’s the shelf life?

A: 5+ years when stored in original packaging

10 Why Choose Our EPTFE-Graphite Packing?

- Custom graphite blends for specific applications

- ISO 9001 & API 622 certified production

- Global technical support network

- Just-in-time delivery options

This comprehensive guide demonstrates how graphite-enhanced EPTFE packing solutions solve critical sealing challenges in demanding industrial environments. The material’s unique combination of properties delivers measurable improvements in reliability, efficiency, and total cost of ownership.