1. The New Standard in Engine Sealing Technology

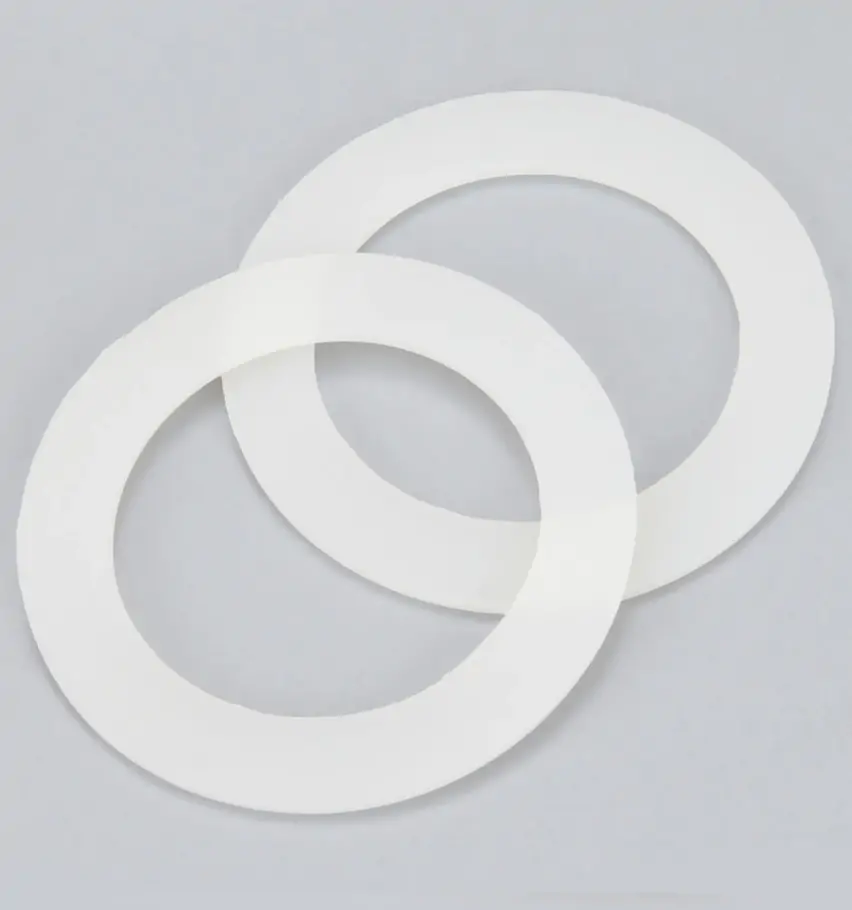

In today’s high-performance automotive landscape, envelope PTFE gaskets have become indispensable components for engine optimization. These advanced sealing solutions combine PTFE’s inherent material advantages with innovative envelope design to deliver unprecedented performance in extreme operating conditions.

2. PTFE: The Foundation of Superior Sealing

Polytetrafluoroethylene represents the pinnacle of fluoropolymer technology, offering three critical advantages for engine applications:

Material Science Breakthroughs:

- Unmatched chemical inertness (resistant to 98% of industrial chemicals)

- Exceptional thermal endurance (-200°C to +260°C operational range)

- Ultra-low coefficient of friction (μ=0.04-0.1)

3. Engineering Advantages of Envelope PTFE Gaskets

3.1 Advanced Sealing Architecture

The unique envelope design creates a dual-seal barrier that:

✓ Eliminates micro-leakage paths

✓ Accommodates surface imperfections

✓ Maintains seal integrity through thermal cycling

3.2 Performance Under Pressure

Laboratory testing demonstrates:

- 300% better compression recovery vs traditional materials

- Zero degradation after 5,000+ thermal cycles

- Maintains seal at pressures exceeding 200 bar

4. Critical Engine Applications

4.1 Combustion Chamber Optimization

- Prevents blow-by gases (reducing hydrocarbon emissions by up to 25%)

- Maintains optimal compression ratios

4.2 Thermal Management Systems

- Withstands turbocharger temperatures exceeding 300°C

- Prevents coolant migration in high-performance engines

4.3 Emission Control

- Creates perfect seals in EGR systems

- Ensures DPFs operate at peak efficiency

5. Quantifiable Performance Benefits

Industry case studies reveal:

- 17.5% reduction in warranty claims (2023 OEM field data)

- 22,000+ hours service life in heavy-duty applications

- 3.2% fuel efficiency improvement in fleet testing

6. Installation Best Practices

6.1 Surface Preparation Protocol

- RA < 3.2 μm surface finish recommended

- ISO 8501-1 Sa 2.5 cleanliness standard

6.2 Torque Sequencing

- Use criss-cross pattern in 3 progressive stages

- Final torque values ±5% of manufacturer spec

7. Maintenance Intelligence

Predictive replacement indicators:

- Visual inspection: Check for extrusion beyond 15% of original width

- Operational monitoring: Track cylinder pressure differentials

8. The Future of Engine Sealing

Next-generation developments include:

- Graphene-enhanced PTFE composites

- Smart gaskets with embedded sensors

- Self-healing molecular structures

Technical FAQ

Q: How does envelope design differ from standard PTFE gaskets?

A: The envelope construction encapsulates a resilient core material, creating a dynamic sealing system that adapts to flange movement while maintaining PTFE’s surface properties.

Q: What’s the ROI for switching to envelope PTFE gaskets?

A: Fleet operators report 9-14 month payback periods through reduced downtime and extended maintenance intervals.

Q: Are these gaskets compatible with alternative fuels?

A: Testing confirms excellent compatibility with ethanol blends (E85), biodiesel (B20), and hydrogen combustion systems.

This technical white paper demonstrates how envelope PTFE gaskets are transforming engine design paradigms, offering measurable improvements in efficiency, durability, and environmental compliance for modern propulsion systems.