When dealing with fluid systems that require high chemical resistance, PTFE (Polytetrafluoroethylene) tube connectors are often the go-to solution. These connectors are essential components in systems that need to handle aggressive chemicals, high temperatures, or sensitive processes. But how do PTFE tube connectors work? Let’s break it down.

PTFE, commonly known by the brand name Teflon, is a synthetic fluoropolymer. It’s famed for its non-reactive properties, making it ideal for use in environments where chemical interaction could compromise the integrity of the system. PTFE tube connectors play a crucial role in connecting PTFE tubing in various configurations, ensuring seamless fluid transfer.

Key Features of PTFE Tube Connectors

- Chemical Resistance: One of the standout features of PTFE tube connectors is their exceptional chemical resistance. This makes them suitable for use in environments exposed to corrosive substances.

- Temperature Tolerance: PTFE can withstand a wide range of temperatures, from very low to extremely high, without losing its structural integrity.

- Non-stick Surface: The non-stick nature of PTFE prevents substances from adhering to the tube connectors, ensuring smooth flow and easy cleaning.

- Durability: PTFE tube connectors are resistant to wear and tear, providing long-lasting performance in demanding applications.

How PTFE Tube Connectors Function

The primary function of PTFE tube connectors is to securely join sections of PTFE tubing, facilitating the creation of a continuous fluid path. Here’s a closer look at how they achieve this:

Sealing and Joining

PTFE tube connectors are designed to create a tight seal, preventing leaks and maintaining the integrity of the fluid system. This is achieved through precision engineering and the use of high-quality materials that complement PTFE’s properties. The connectors often feature compression fittings, which apply pressure to the tubing, creating a secure seal.

Versatility in Applications

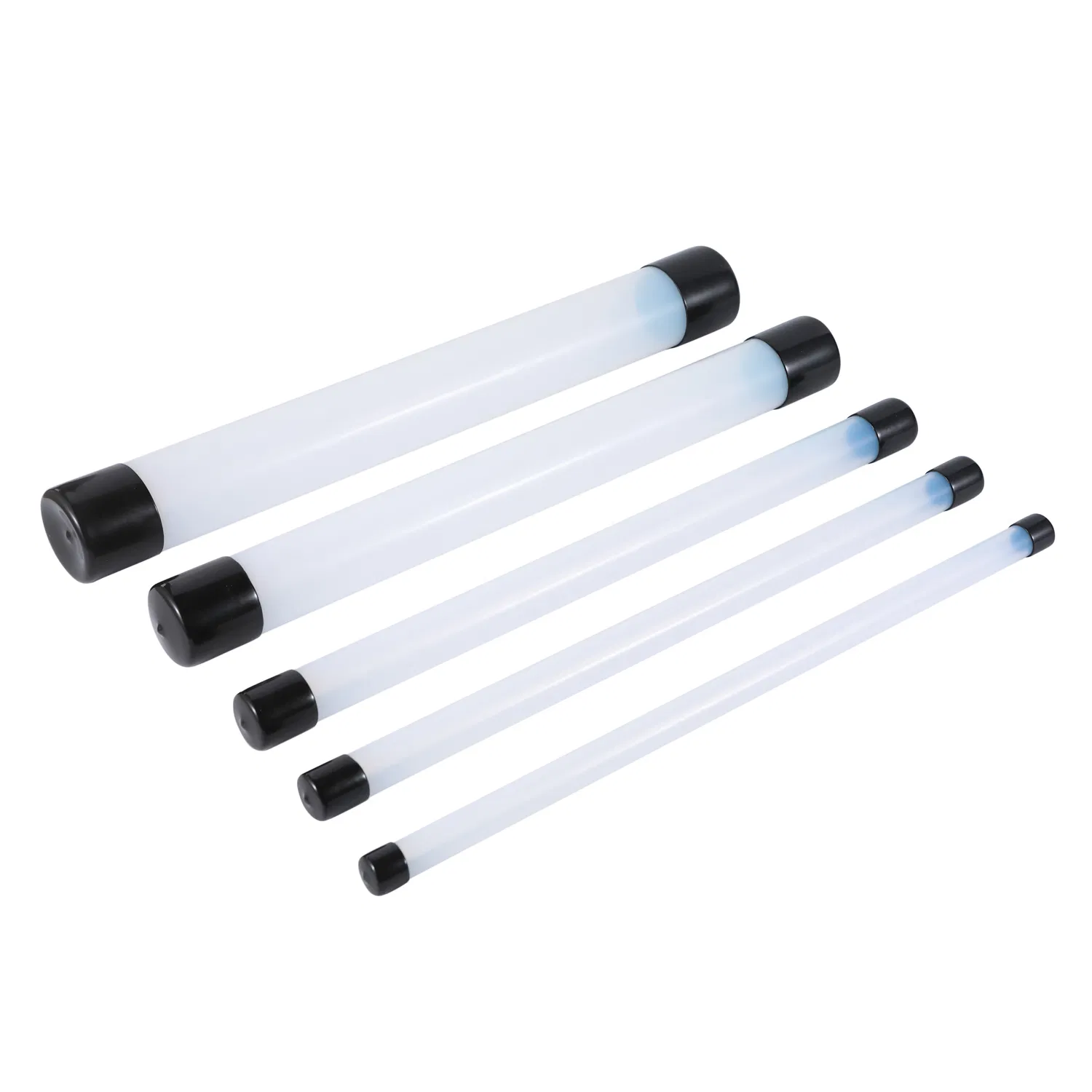

PTFE tube connectors are utilized in a variety of applications, from laboratory equipment to industrial machinery. They can be found in systems that require the handling of gases, liquids, and even semi-solids. Their versatility is enhanced by the availability of various connector types, including straight connectors, elbows, and tees, allowing for customized configurations.

Installation of PTFE Tube Connectors

Installing PTFE tube connectors involves a straightforward process. First, ensure that the ends of the PTFE tubing are clean and free from debris. Insert the tubing into the connector and tighten the fitting to achieve a snug fit. The compression mechanism ensures that the tubing is held securely in place, preventing any movement that could lead to leaks.

In conclusion, PTFE tube connectors are integral to fluid systems that demand high chemical resistance and durability. Their ability to create secure, leak-proof connections makes them indispensable in many industries. Whether you’re working in a lab or an industrial setting, understanding how these connectors work can help you optimize your system’s performance.