Removing a PTFE tube, often referred to as a Teflon tube, can be a straightforward process with the right technique and tools. Whether you’re dealing with a 3D printer, pneumatic systems, or any other application, understanding how to properly disassemble PTFE tubing will ensure you don’t damage the tubing or the fittings. Here’s a guide on how to efficiently pull out a PTFE tube.

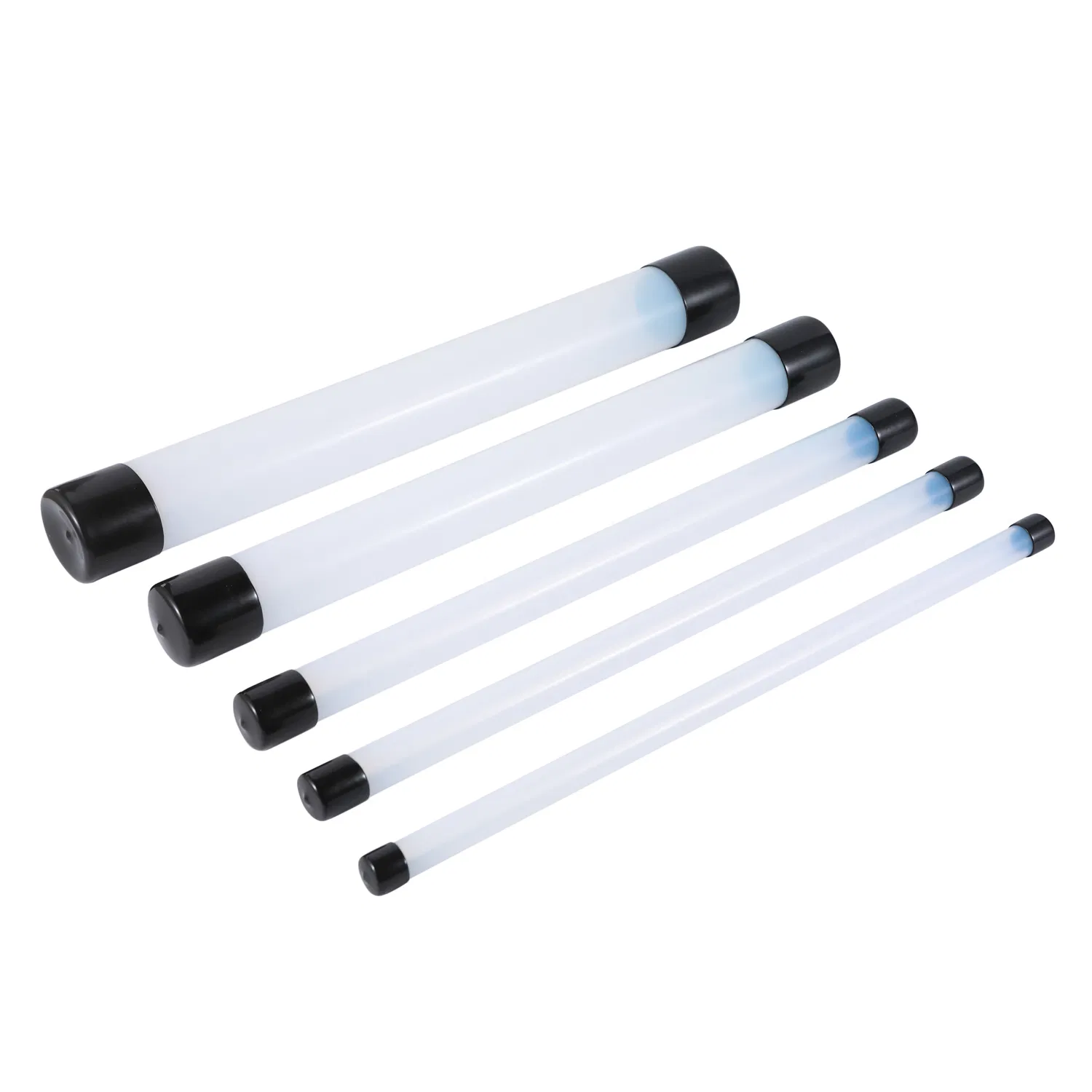

Before diving into the removal process, it’s essential to grasp what PTFE tubing is. PTFE, or polytetrafluoroethylene, is a versatile material known for its high resistance to heat and chemicals. Its slippery surface makes it ideal for various applications, but it also requires careful handling during installation and removal.

To successfully remove a PTFE tube, gather the following tools:

- PTFE Tube Removal Tool: Specifically designed for this purpose, it helps avoid damage during extraction.

- Wrench or Pliers: To loosen any fittings securing the tube.

- Safety Gloves: To protect your hands during the process.

Steps to Remove PTFE Tube

1. Prepare the Area

Ensure the system is turned off and depressurized. This is crucial, especially in pneumatic or fluid systems, to prevent accidents or injuries.

2. Loosen the Fittings

Using a wrench or pliers, gently loosen the fittings holding the PTFE tube. Be careful not to apply excessive force, which could damage the fittings or the tube itself. If the fittings are stubborn, apply a small amount of lubricant to ease the process.

3. Use the PTFE Tube Removal Tool

Insert the PTFE tube removal tool around the tube. This tool is designed to grip the tube without causing abrasions or deformation. Gently pull the tool along the length of the tube to dislodge it from the fitting.

4. Gently Extract the Tube

With the tube now loosened, carefully pull it out by hand. If it feels stuck, recheck the fittings to ensure they are entirely loosened. Avoid yanking the tube, as this could cause damage.

Tips for Reinstallation

Once you’ve removed the PTFE tube, you may need to reinstall it. Here are some tips for a smooth reinstallation:

- Check for Damage: Inspect the tube for any signs of wear or damage. If the tube is compromised, consider replacing it.

- Cut Cleanly: If you need to cut the tube, ensure it’s a clean, straight cut to fit snugly into the fittings.

- Secure Properly: When reinstalling, ensure the fittings are tightened just enough to hold the tube securely without over-tightening.

By following these steps and tips, you’ll ensure a smooth process in both removing and reinstalling PTFE tubes, maintaining the integrity of your system and equipment. If you have any further questions or need additional guidance, feel free to reach out in the comments below.