When it comes to industrial sealing solutions, choosing the right gasket can make a significant difference in performance and durability. Glass fiber PTFE gaskets are increasingly popular due to their enhanced sealing capabilities and diverse applications. This article delves into the world of glass fiber PTFE gaskets, explaining what they are, their benefits, and how they can be the ideal choice for your sealing needs.

Understanding PTFE Gaskets

Polytetrafluoroethylene, or PTFE, is a synthetic polymer known for its non-stick properties and resistance to heat and chemicals. Commonly recognized by the brand name Teflon, PTFE gaskets are used in a variety of industries due to their reliability and efficiency.

The Composition and Properties of PTFE

PTFE is composed of carbon and fluorine atoms, which give it a unique set of properties. Its high molecular weight and linear polymer structure contribute to its outstanding chemical resistance. The strong carbon-fluorine bonds make it exceptionally stable, allowing it to withstand corrosive environments without degrading. This chemical inertness is one reason why PTFE is favored in applications where reactivity needs to be minimal.

Manufacturing Process of PTFE Gaskets

The manufacturing process of PTFE gaskets involves several steps to ensure high quality and performance. Initially, PTFE resins are molded into the desired shape through compression molding. After molding, the material undergoes sintering, a heat treatment process that enhances its mechanical properties. This process not only improves the density and strength of the PTFE but also ensures that it retains its beneficial properties like non-stickiness and thermal resistance.

Applications of Standard PTFE Gaskets

Standard PTFE gaskets are widely used across various industries due to their versatile properties. In the chemical industry, they are utilized for sealing applications involving aggressive chemicals. In the food industry, PTFE gaskets ensure hygiene and safety due to their non-reactive nature. They are also common in the automotive and aerospace sectors, where their ability to function under extreme temperatures is highly valued.

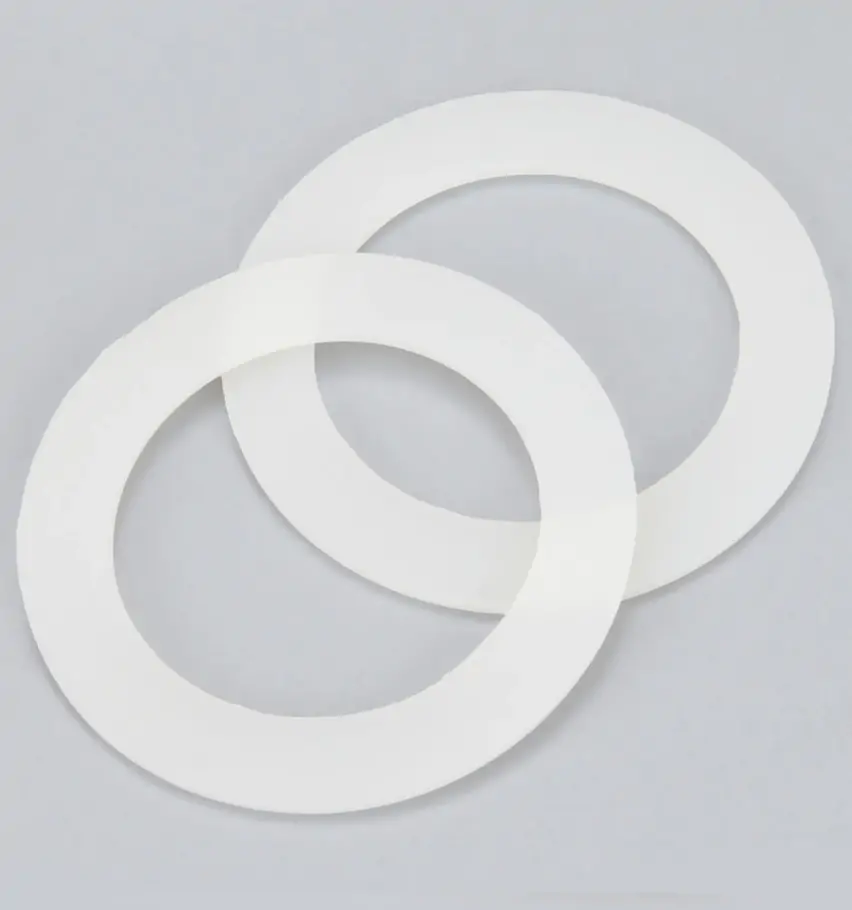

What are Glass Fiber PTFE Gaskets?

Glass fiber PTFE gaskets are a specific type of PTFE gasket that is reinforced with glass fibers. This reinforcement enhances the mechanical strength of the gasket while retaining the chemical resistance and thermal stability of PTFE. The addition of glass fibers makes these gaskets more robust and suitable for demanding applications.

The Role of Glass Fibers in Gaskets

The integration of glass fibers within PTFE gaskets plays a crucial role in enhancing their performance. Glass fibers are known for their high tensile strength and resistance to wear and tear. When embedded into PTFE, they provide additional structural integrity, making the gaskets more resilient under mechanical stress. This reinforcement is particularly beneficial in applications where the gasket is subject to frequent pressure changes or mechanical loads.

Advantages Over Conventional Gaskets

Glass fiber PTFE gaskets offer several advantages over conventional gaskets made from other materials. Unlike rubber or standard PTFE gaskets, the glass fiber reinforced versions are less likely to compress or deform under pressure. This resistance to deformation ensures a more reliable seal over a longer period. Additionally, their superior thermal stability allows them to maintain effectiveness in fluctuating temperature environments, unlike some other gasket materials that may degrade or lose their sealing capabilities.

Design and Customization Options

Manufacturers offer a wide range of design and customization options for glass fiber PTFE gaskets to meet specific industrial needs. These gaskets can be produced in various shapes and sizes, tailored to fit different equipment or machinery requirements. Furthermore, they can be customized with additional features such as anti-static properties or enhanced surface finishes to further optimize their performance for particular applications. This flexibility in design makes them a preferred choice in specialized industries.

Benefits of Glass Fiber Filled PTFE Sealing Gaskets

Enhanced Durability and Strength

One of the primary advantages of glass fiber PTFE gaskets is their enhanced durability. The glass fibers provide additional strength, making the gaskets more resistant to mechanical stress and deformation. This makes them ideal for high-pressure applications where standard PTFE gaskets might fail.

Resistance to Wear and Tear

Glass fiber PTFE gaskets exhibit exceptional resistance to wear and tear, significantly extending their lifespan compared to non-reinforced gaskets. The glass fibers act as a shield against abrasive forces that commonly occur in industrial settings. This durability is essential in applications where gaskets are subject to continuous movement or vibration, ensuring a consistent seal without frequent replacements.

Performance Under High Pressure

In high-pressure environments, maintaining a reliable seal is critical to prevent leaks and ensure operational safety. Glass fiber PTFE gaskets excel under such conditions due to their reinforced structure. The glass fibers help distribute pressure evenly across the gasket, minimizing the risk of blowouts or failures. This capability makes them indispensable in industries like oil and gas, where high-pressure sealing is a routine requirement.

Long-term Reliability

The combination of PTFE’s inherent properties and the added strength of glass fibers results in a gasket that offers long-term reliability. These gaskets maintain their performance over extended periods, reducing the need for frequent inspections and replacements. This longevity translates into lower maintenance costs and increased operational efficiency, making them a cost-effective choice for businesses.

Excellent Chemical Resistance

Glass fiber PTFE gaskets maintain the excellent chemical resistance that PTFE is known for. This makes them suitable for use in environments where they may be exposed to aggressive chemicals or corrosive substances. Whether dealing with acids, solvents, or bases, these gaskets can handle them all.

Versatility in Chemical Environments

The outstanding chemical resistance of glass fiber PTFE gaskets makes them highly versatile across various chemical environments. They can withstand exposure to a wide range of substances, from strong acids and bases to organic solvents. This versatility ensures their suitability in numerous industries, including pharmaceuticals, where purity and non-reactivity are paramount.

Stability in Corrosive Conditions

Corrosive conditions can quickly degrade many materials, but glass fiber PTFE gaskets are designed to withstand such harsh environments. The PTFE component resists chemical attack, while the glass fibers add an extra layer of protection against mechanical degradation. This combination ensures that the gaskets remain stable and effective, even when exposed to corrosive chemicals over long periods.

Compatibility with a Range of Chemicals

Glass fiber PTFE gaskets demonstrate compatibility with an extensive range of chemicals, reducing the risk of adverse reactions. This compatibility is crucial for industries that use a variety of chemical processes, as it ensures the gaskets do not compromise the integrity of the systems they are part of. Their ability to function seamlessly with different chemicals enhances their appeal in diverse industrial applications.

Superior Temperature Stability

Another key benefit is their ability to withstand extreme temperatures. Glass fiber PTFE gaskets perform well in both high and low-temperature environments, maintaining their sealing integrity without losing effectiveness. This makes them versatile across various industrial applications.

Performance in High-Temperature Applications

In high-temperature applications, maintaining a reliable seal is crucial to prevent leaks and ensure safety. Glass fiber PTFE gaskets excel in such conditions due to their exceptional thermal stability. They can withstand temperatures that would cause other materials to degrade or lose effectiveness, making them ideal for use in environments like power plants and chemical processing facilities.

Cold Temperature Reliability

Just as they perform well in high temperatures, glass fiber PTFE gaskets also maintain their integrity in cold environments. This cold temperature reliability is particularly important in industries such as refrigeration and aerospace, where components are frequently exposed to low temperatures. The ability of these gaskets to remain flexible and effective in cold conditions ensures a consistent seal, preventing leaks and ensuring operational efficiency.

Thermal Cycling Endurance

In many industrial applications, components are subject to thermal cycling, where temperatures fluctuate significantly. Glass fiber PTFE gaskets are designed to endure these cycles without compromising their sealing capabilities. The combination of PTFE’s inherent properties and the reinforcement provided by glass fibers ensures they can handle repeated temperature changes without losing performance, making them a reliable choice for dynamic environments.

Low Friction and Non-Stick Properties

The non-stick properties of PTFE are retained in glass fiber PTFE gaskets, which help reduce friction and wear over time. This prolongs the lifespan of the gasket and the machinery it is used in, leading to cost savings in maintenance and replacements.

Reducing Operational Friction

Glass fiber PTFE gaskets contribute to reducing operational friction in machinery and equipment. The low-friction surface minimizes resistance, allowing components to move smoothly against each other. This reduction in friction not only enhances the efficiency of the equipment but also reduces the energy consumption required for operation, resulting in cost savings over time.

Minimizing Wear and Tear

The non-stick properties of glass fiber PTFE gaskets play a crucial role in minimizing wear and tear on both the gasket and the machinery. By reducing the friction between components, these gaskets help prevent abrasion and degradation. This prolongs the lifespan of the equipment, reducing the need for frequent maintenance and part replacements, ultimately leading to increased operational efficiency.

Enhancing Equipment Longevity

The combination of low friction and non-stick properties enhances the longevity of both the gasket and the equipment it is used in. By minimizing wear and tear, glass fiber PTFE gaskets help maintain the integrity of the machinery over extended periods. This results in fewer breakdowns, reduced downtime, and lower maintenance costs, contributing to the overall cost-effectiveness of industrial operations.

Applications of Glass Fiber PTFE Gaskets

Chemical Processing Industry

In the chemical processing industry, the need for gaskets that can withstand aggressive chemicals is paramount. Glass fiber PTFE gaskets provide the necessary chemical resistance, making them a reliable choice for sealing pumps, valves, and reactors.

Sealing Challenges in Chemical Processing

Chemical processing environments present unique sealing challenges due to the aggressive nature of the substances involved. Gaskets in this industry must withstand exposure to strong acids, bases, and solvents, all of which can compromise the integrity of standard sealing materials. Glass fiber PTFE gaskets address these challenges by offering superior chemical resistance, ensuring a reliable seal even in the most demanding conditions.

Importance of Chemical Resistance

Chemical resistance is a critical factor in selecting gaskets for the chemical processing industry. Glass fiber PTFE gaskets excel in this regard, maintaining their structural integrity and sealing capabilities when exposed to a wide range of chemicals. This resistance ensures that processes remain safe and efficient, preventing leaks and contamination that could lead to costly disruptions.

Applications in Equipment and Machinery

Glass fiber PTFE gaskets are commonly used in various equipment and machinery within the chemical processing industry. They are ideal for sealing pumps, valves, and reactors, where maintaining a reliable seal is crucial to prevent leaks and ensure operational efficiency. Their ability to withstand aggressive chemicals and temperature fluctuations makes them a preferred choice for critical sealing applications.

Oil and Gas Sector

The oil and gas sector often deals with high pressures and temperatures. Glass fiber PTFE gaskets are well-suited for these conditions, offering durability and reliability in sealing applications such as pipelines and pressure vessels.

High-Pressure Sealing Requirements

In the oil and gas sector, sealing applications often involve high pressures that demand robust and reliable gasket solutions. Glass fiber PTFE gaskets are designed to withstand these pressures, ensuring a secure seal that prevents leaks and maintains the integrity of the system. Their durability and strength make them a preferred choice for high-pressure sealing applications in pipelines and pressure vessels.

Temperature Extremes in Oil and Gas

Temperature extremes are common in the oil and gas industry, requiring gaskets that can maintain their sealing capabilities in both high and low-temperature environments. Glass fiber PTFE gaskets excel in these conditions, offering exceptional thermal stability that ensures a reliable seal regardless of temperature fluctuations. This reliability is essential for maintaining safety and efficiency in oil and gas operations.

Applications in Exploration and Production

Glass fiber PTFE gaskets are widely used in exploration and production activities within the oil and gas sector. They are employed in sealing applications such as wellheads, pipelines, and pressure vessels, where maintaining a reliable seal is crucial to prevent leaks and ensure operational efficiency. Their ability to withstand high pressures and temperature extremes makes them an ideal choice for critical sealing applications in these demanding environments.

Food and Beverage Industry

For industries like food and beverage, maintaining hygiene and safety standards is crucial. Glass fiber PTFE gaskets are non-reactive and non-toxic, making them suitable for use in equipment that comes into contact with food products.

Hygiene and Safety Standards

Maintaining hygiene and safety standards is of utmost importance in the food and beverage industry. Glass fiber PTFE gaskets contribute to these standards by providing a reliable sealing solution that is non-reactive and non-toxic. Their chemical inertness ensures that there is no risk of contamination, making them ideal for use in equipment that comes into contact with food products.

Non-Reactive Sealing Solutions

Non-reactivity is a key requirement for gaskets used in the food and beverage industry, as any reactivity could compromise the quality and safety of the products. Glass fiber PTFE gaskets meet this requirement by offering a non-reactive sealing solution that maintains the purity and integrity of food products. Their resistance to chemical interaction ensures that the gaskets do not affect the taste, odor, or safety of the products.

Applications in Food Processing Equipment

Glass fiber PTFE gaskets are commonly used in various food processing equipment, where maintaining a reliable seal is crucial to prevent leaks and ensure operational efficiency. They are employed in sealing applications such as mixers, blenders, and conveyor systems, where their non-reactive properties ensure the safety and quality of the food products. Their versatility and reliability make them a preferred choice for sealing applications in the food and beverage industry.

Pharmaceutical Industry

In the pharmaceutical industry, the chemical resistance and non-stick properties of glass fiber PTFE gaskets are highly valued. They are often used in sealing applications within production equipment and containment systems.

Sealing Challenges in Pharmaceutical Production

The pharmaceutical industry presents unique sealing challenges due to the need for maintaining purity and preventing contamination. Glass fiber PTFE gaskets address these challenges by offering superior chemical resistance and non-stick properties, ensuring a reliable seal that maintains the integrity of the production process. Their ability to withstand aggressive chemicals and temperature fluctuations makes them a preferred choice for critical sealing applications in pharmaceutical production.

Importance of Chemical Resistance

Chemical resistance is a critical factor in selecting gaskets for the pharmaceutical industry. Glass fiber PTFE gaskets excel in this regard, maintaining their structural integrity and sealing capabilities when exposed to a wide range of chemicals. This resistance ensures that processes remain safe and efficient, preventing leaks and contamination that could lead to costly disruptions.

Applications in Production and Containment

Glass fiber PTFE gaskets are commonly used in various production and containment equipment within the pharmaceutical industry. They are ideal for sealing applications such as reactors, mixers, and filtration systems, where maintaining a reliable seal is crucial to prevent leaks and ensure operational efficiency. Their ability to withstand aggressive chemicals and temperature fluctuations makes them a preferred choice for critical sealing applications in these demanding environments.

Selecting the Right Glass Fiber PTFE Gasket

When selecting a glass fiber PTFE gasket, consider the specific requirements of your application. Factors such as temperature range, chemical exposure, and mechanical stress should guide your choice. Consulting with a gasket specialist can help ensure you select the right product for your needs.

Assessing Application Requirements

Selecting the right glass fiber PTFE gasket begins with a thorough assessment of the application requirements. Consider factors such as the operating temperature range, chemical exposure, and mechanical stress that the gasket will encounter. Understanding these requirements is crucial to choosing a gasket that will perform optimally in the specific application.

Consulting with Experts

Consulting with experts in gasket technology can provide valuable insights and guidance in selecting the right product. Gasket specialists have the expertise to recommend the most suitable glass fiber PTFE gasket based on the specific needs of the application. Their knowledge of the latest advancements in gasket materials and technology ensures that you receive a solution that meets your requirements.

Customization Options

Customization options are available to tailor glass fiber PTFE gaskets to the specific needs of the application. Manufacturers offer a range of design and customization options, including different shapes, sizes, and features, to ensure that the gasket fits the equipment perfectly. Customization ensures that the gasket provides optimal performance and reliability in the intended application.

Installation Tips

Proper installation is key to maximizing the performance of glass fiber PTFE gaskets. Ensure that the sealing surfaces are clean and free from debris. Follow the manufacturer’s guidelines for torque settings to avoid over-compression, which can damage the gasket.

Preparing the Sealing Surfaces

Before installing glass fiber PTFE gaskets, it’s important to prepare the sealing surfaces by cleaning them thoroughly. Any debris, dirt, or residue on the surfaces can compromise the integrity of the seal. Use appropriate cleaning agents and tools to ensure that the surfaces are free from contaminants, ensuring a reliable seal and optimal gasket performance.

Following the Manufacturer’s Guidelines

Adhering to the manufacturer’s guidelines is crucial for the successful installation of glass fiber PTFE gaskets. These guidelines include recommendations for torque settings, installation techniques, and maintenance procedures. Following these guidelines ensures that the gasket is installed correctly, providing a reliable seal that meets the application’s requirements.

Avoiding Over-Compression

Over-compression is a common issue that can damage glass fiber PTFE gaskets and compromise their performance. To avoid over-compression, use the recommended torque settings provided by the manufacturer. Proper torque application ensures that the gasket is compressed evenly, maintaining its structural integrity and sealing capabilities.

Conclusion

Glass fiber PTFE gaskets offer a robust and versatile solution for various sealing applications. Their combination of strength, chemical resistance, and thermal stability makes them an excellent choice for industries ranging from chemical processing to food and beverage. By understanding their benefits and applications, you can make an informed decision to enhance the sealing efficiency and longevity of your equipment.

Incorporating glass fiber PTFE gaskets into your operations can result in improved performance, reduced maintenance costs, and greater reliability. Consider these gaskets for your next sealing project and experience the advantages they bring.

Advantages of Glass Fiber PTFE Gaskets

Glass fiber PTFE gaskets provide numerous advantages that make them a superior choice for sealing applications. Their enhanced durability and strength ensure reliable performance in high-pressure and high-temperature environments. The excellent chemical resistance and non-stick properties further enhance their suitability for a wide range of industrial applications. By choosing glass fiber PTFE gaskets, you can enhance the efficiency, safety, and reliability of your operations.

Future Trends in Sealing Technology

The sealing technology industry continues to evolve, with advancements in materials and design driving improvements in gasket performance. Future trends in sealing technology are likely to focus on enhancing the properties of glass fiber PTFE gaskets even further, with innovations aimed at increasing their durability, chemical resistance, and thermal stability. Staying informed about these trends can help you make informed decisions and ensure that your sealing solutions remain at the forefront of technological advancements.

Making an Informed Decision

When selecting sealing solutions, it’s essential to make an informed decision based on the specific requirements of your application. Glass fiber PTFE gaskets offer a reliable and cost-effective solution that meets the needs of various industries. By understanding their benefits and applications, you can choose a gasket that enhances the performance and longevity of your equipment, ultimately contributing to the success of your operations.