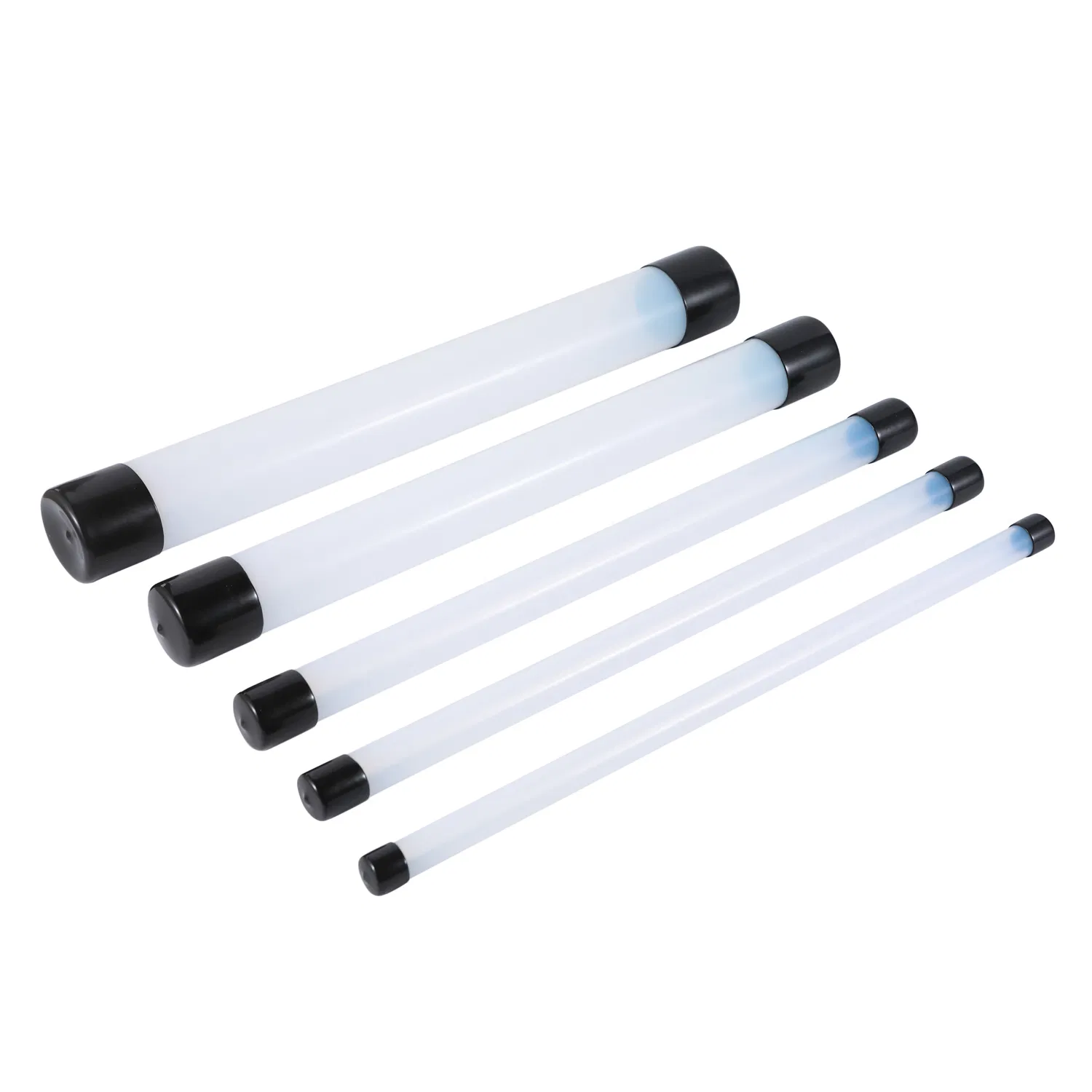

Cutting PTFE (Polytetrafluoroethylene) tubing, commonly known by the brand name Teflon, can be a daunting task due to its slick, non-stick surface and flexibility. However, with the right techniques and tools, you can achieve clean and precise cuts. Whether you’re an engineer, a hobbyist, or someone working with PTFE in industrial applications, this guide will equip you with practical methods for cutting PTFE tubing effectively.

PTFE tubing is renowned for its resistance to heat, chemicals, and electrical conductivity. Due to these characteristics, it’s extensively used in various industries, including automotive, chemical, and food processing. Understanding the properties of PTFE will help you choose the right cutting techniques and tools.

Tools Required for Cutting PTFE

Le key to achieving clean PTFE tube cuts lies in selecting the appropriate cutting tools. Here are some of the most effective tools you can use:

- Tube Cutter: Specifically designed for cutting plastic tubes, these cutters offer precision and ease.

- Utility Knife: Ideal for smaller diameters; ensure the blade is sharp for a clean cut.

- Hacksaw: Useful for thicker tubes, though it may require deburring afterward.

- Hot Knife: Provides a smooth edge by melting through the tube.

Step-by-Step Guide to Cutting PTFE Tubing

Preparation

Before you begin, it’s crucial to gather all necessary tools and materials. Ensure you have a stable work surface and adequate lighting. Measure the exact length needed, and mark the cutting line using a non-permanent marker for accuracy.

Cutting Process

- Secure the Tube: Use a clamp or a vise to hold the PTFE tube securely in place. This prevents movement during cutting and helps maintain precision.

- Choose the Right Tool: Depending on the tube size and thickness, select the most suitable cutting tool. For smaller tubes, a tube cutter or utility knife works best, while thicker tubes may require a hacksaw.

- Make the Cut: Align the tool with the marked cutting line. If using a tube cutter, rotate it around the tube while applying gentle pressure. For a utility knife, glide the blade along the line steadily. Hacksaw users should make slow, even strokes to avoid jagged edges.

- Inspect the Cut: After cutting, check the edge for cleanliness. A clean cut will have a smooth finish with no frayed edges. If necessary, use sandpaper or a deburring tool to refine the edge further.

Tips for Precision Cutting

- Always use sharp blades to avoid crushing the tube.

- For consistent results, practice on a scrap piece of PTFE tubing.

- When using a hot knife, ensure proper ventilation to avoid inhaling any fumes.

By following these techniques, you can achieve precise and clean cuts on PTFE tubing, enhancing the quality and performance of your projects. Whether you’re cutting small or large diameter tubes, these methods will ensure your work is efficient and accurate.