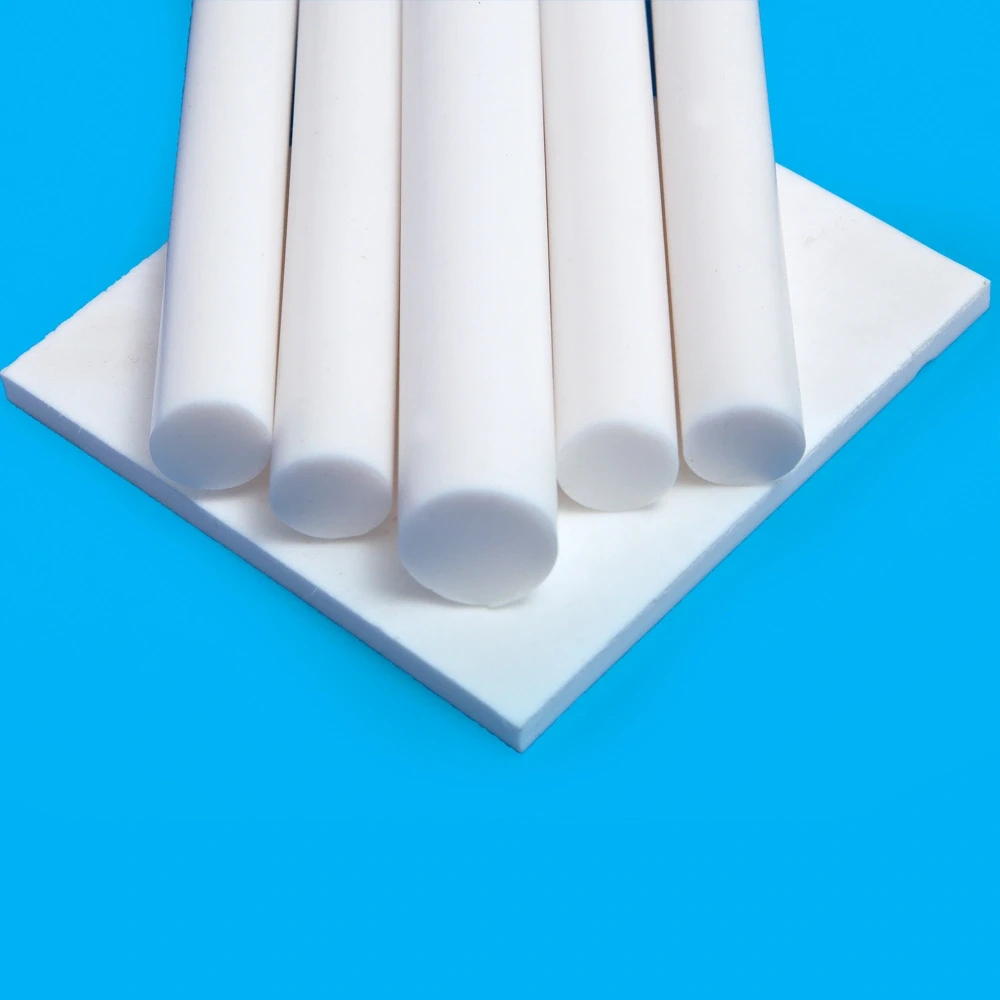

In the world of materials, PTFE, or polytetrafluoroethylene, is a name that consistently stands out due to its remarkable properties. Its versatility and unique characteristics make it indispensable across various sectors. However, did you know that filled PTFE rods can provide even more advantages? By enhancing PTFE with various fillers, these rods become even more versatile and useful for a wide range of applications, offering solutions that plain PTFE might not.

What is Filled PTFE?

To understand filled PTFE rods, we first need to grasp the basics of PTFE itself. Known for its non-stick properties, PTFE is a synthetic fluoropolymer of tetrafluoroethylene. It has carved out a niche in various industries due to its unique properties.

The Basics of PTFE

PTFE is primarily recognized for its low friction, excellent chemical resistance, and high-temperature tolerance. It can withstand harsh environments that would degrade other materials. These properties make it a preferred choice in applications ranging from cookware to industrial machinery.

Transforming PTFE with Fillers

By introducing fillers such as glass, carbon, or graphite, the physical properties of PTFE are significantly enhanced. This transformation enables PTFE to expand its usability in environments that require more than just its inherent properties. Fillers can be tailored to impart specific characteristics, thereby broadening the scope of PTFE’s applications.

The Science Behind Fillers

The addition of fillers alters the microstructure of PTFE, leading to modifications in its mechanical and thermal properties. Each type of filler interacts with the PTFE matrix differently, resulting in varied enhancements. Understanding these interactions is crucial for selecting the right-filled PTFE for specific applications.

Types of Fillers

Each filler brings its own set of properties to the table, altering the PTFE’s capabilities in unique ways. The choice of filler depends largely on the intended application and the specific performance requirements of the material.

Glass Filled PTFE

Adding glass to PTFE increases its compressive strength and wear resistance. This enhancement is particularly useful in applications where the material is subjected to high mechanical stress. Glass-filled PTFE is often used in seals, bearings, and other components that endure continuous pressure.

Carbon Filled PTFE

This filler improves the thermal conductivity and wear resistance of PTFE. Carbon-filled PTFE rods are often used in dynamic seals and bearings due to their excellent performance under high pressure. They are ideal for applications where thermal management is crucial, as they effectively dissipate heat.

Graphite Filled PTFE

When graphite is added, PTFE becomes more electrically conductive and offers improved wear properties. It’s ideal for applications needing a high degree of lubrication. This makes graphite-filled PTFE suitable for use in environments where reducing friction and increasing conductivity are priorities.

Bronze Filled PTFE

Bronze fillers increase the hardness and dimensional stability of PTFE, making it suitable for high-load applications. These rods are commonly used in heavy machinery and equipment that require materials with high strength and stability. The bronze filler ensures that the PTFE can withstand significant stress without deforming.

Nickel Filled PTFE

This filler enhances the material’s electrical conductivity and wear resistance, making it suitable for specialized electrical applications. Nickel-filled PTFE is ideal for applications where both conductivity and durability are essential. It has applications in industries such as electronics and telecommunications.

Advantages of Filled PTFE Rods

Filled PTFE rods offer a multitude of benefits that make them a valuable asset in various industrial applications. By tailoring the PTFE with specific fillers, these rods can meet and exceed the demands of challenging environments.

Enhanced Mechanical Properties

One of the most significant benefits of filled PTFE rods is their improved mechanical strength. Fillers like glass and carbon add durability, making the rods more suitable for heavy-duty applications. This means you can use them in environments where plain PTFE would fall short due to stress or wear.

The increased compressive strength ensures that filled PTFE rods can handle more pressure without deforming. This is particularly crucial in industries where machinery and components are subjected to constant stress and strain. Additionally, the improved wear resistance means these rods have a longer lifespan, reducing the need for frequent replacements.

Improved Thermal Conductivity

In high-temperature applications, thermal management is crucial. Carbon-filled PTFE, for instance, offers improved thermal conductivity, which is essential for heat dissipation. This property enables the use of filled PTFE rods in applications where heat buildup could otherwise pose a problem.

Effective thermal management ensures that machinery and components operate efficiently without overheating. This is especially important in sectors such as the automotive and aerospace industries, where temperature fluctuations can significantly impact performance. The ability of filled PTFE rods to manage heat effectively makes them invaluable in such settings.

Reduced Deformation Under Load

Glass and carbon fillers contribute to reducing deformation under load, a common issue with pure PTFE. This makes filled PTFE rods ideal for applications where they will be subjected to significant weight or pressure over time. The structural integrity of these rods ensures they maintain their shape and function even under extreme conditions.

This property is particularly beneficial in heavy machinery and industrial equipment, where components are subjected to continuous stress. By minimizing deformation, filled PTFE rods help maintain the efficiency and reliability of the machinery, leading to improved overall performance.

Superior Chemical Resistance

While PTFE is already known for its chemical resistance, filled PTFE maintains this property while also offering additional benefits. It’s resistant to almost all industrial chemicals, making it suitable for use in aggressive chemical environments. The fillers do not compromise the chemical resistance of PTFE, ensuring that it remains effective even in the most demanding conditions.

This makes filled PTFE rods ideal for use in the chemical processing industry, where exposure to corrosive substances is a common occurrence. The rods can withstand these environments without degrading, ensuring longevity and reliability in demanding applications.

Low Friction and Wear

The inherent low-friction quality of PTFE is preserved in filled rods, with added wear resistance thanks to the fillers. This makes them ideal for applications such as bearings and bushings, where low friction and high wear resistance are crucial. The combination of these properties ensures smooth operation and minimal maintenance.

In applications involving moving parts, reducing friction is crucial to prevent wear and tear. Filled PTFE rods excel in such environments, offering both the low friction needed for smooth movement and the wear resistance necessary for durability.

Applications of Filled PTFE Rods

Filled PTFE rods have carved out niches in various industries thanks to their enhanced properties. Their versatility and adaptability make them suitable for a wide range of applications.

Automotive Industry

In the automotive industry, filled PTFE rods are used in various components, from seals to bearings. Their ability to withstand high temperatures and aggressive chemicals makes them a favorite in this sector. The durability and reliability of filled PTFE rods ensure that automotive components operate efficiently and safely.

The automotive industry demands materials that can endure harsh environments and constant stress. Filled PTFE rods meet these requirements, providing solutions that enhance vehicle performance and longevity. Their use in critical components, such as engines and transmissions, underscores their importance in this sector.

Chemical Processing

Due to their excellent chemical resistance, filled PTFE rods are commonly used in the chemical processing industry. They can be found in pumps, valves, and other components that come in contact with harsh chemicals. The ability to resist corrosion and degradation makes them ideal for such environments.

In chemical processing, equipment is often exposed to corrosive substances that can damage materials over time. Filled PTFE rods provide the necessary protection, ensuring that equipment remains functional and efficient. Their use helps minimize downtime and maintenance costs, improving overall productivity.

Electrical Applications

Nickel- and graphite-filled PTFE rods have enhanced electrical conductivity, making them suitable for specific electrical applications, such as semiconductor production. These rods offer a unique combination of conductivity and durability, essential for the demands of the electronics industry.

In electrical applications, materials must provide both performance and safety. Filled PTFE rods deliver on both fronts, ensuring that electrical components operate efficiently and safely. Their use in semiconductors and other electronic devices highlights their critical role in this industry.

Food and Beverage Industry

The non-toxic nature of PTFE, combined with its resistance to high temperatures and chemicals, makes filled PTFE rods ideal for use in food processing equipment. These rods ensure that food products are processed safely and efficiently, maintaining high standards of quality and hygiene.

In the food and beverage industry, materials must meet stringent safety and quality standards. Filled PTFE rods offer the necessary properties, ensuring that equipment operates without contaminating food products. Their use helps maintain the integrity and safety of food processing operations.

Selecting the Right-Filled PTFE Rod

When selecting a filled PTFE rod for your application, consider the specific requirements such as load, temperature, and chemical exposure. Each type of filled PTFE has unique properties that make it suitable for different environments and applications.

Matching Fillers to Applications

For instance, if you need a rod for high-load applications, a bronze-filled PTFE rod might be your best choice. On the other hand, if electrical conductivity is a priority, nickel or graphite-filled options would be more appropriate. Understanding the specific needs of your application will guide you in selecting the right filled PTFE rod.

Evaluating Performance Requirements

Consider the performance requirements of your application, such as wear resistance, thermal management, and chemical resistance. Each filled PTFE type offers distinct advantages, so it’s essential to match these with your application’s demands. This ensures that you select a rod that not only meets but exceeds your performance expectations.

Where to Buy Filled PTFE Rods

When purchasing filled PTFE rods, it’s crucial to find a reliable supplier. You can find a range of options, from wholesale PTFE carbon-filled tubes to molded PTFE rods, at specialized manufacturers and distributors. Ensure that you consider factors such as quality, pricing, and the supplier’s industry reputation.

A reputable supplier will offer high-quality filled PTFE rods that meet industry standards. They can also provide guidance on selecting the right type of rod for your specific needs. By choosing a trusted supplier, you can ensure that you receive a product that delivers optimal performance and durability.

Conclusion

Filled PTFE rods offer a range of advantages, making them indispensable in various industries. By understanding the benefits and applications of different fillers, you can make informed decisions that enhance the performance and longevity of your products.

Whether you’re in the automotive, chemical, or food processing industry, filled PTFE rods offer the durability and reliability you need to excel. By choosing the right type of filled PTFE rod for your application, you can ensure optimal performance and efficiency. Embrace the possibilities that PTFE rods offer, and elevate your applications to new heights of success.