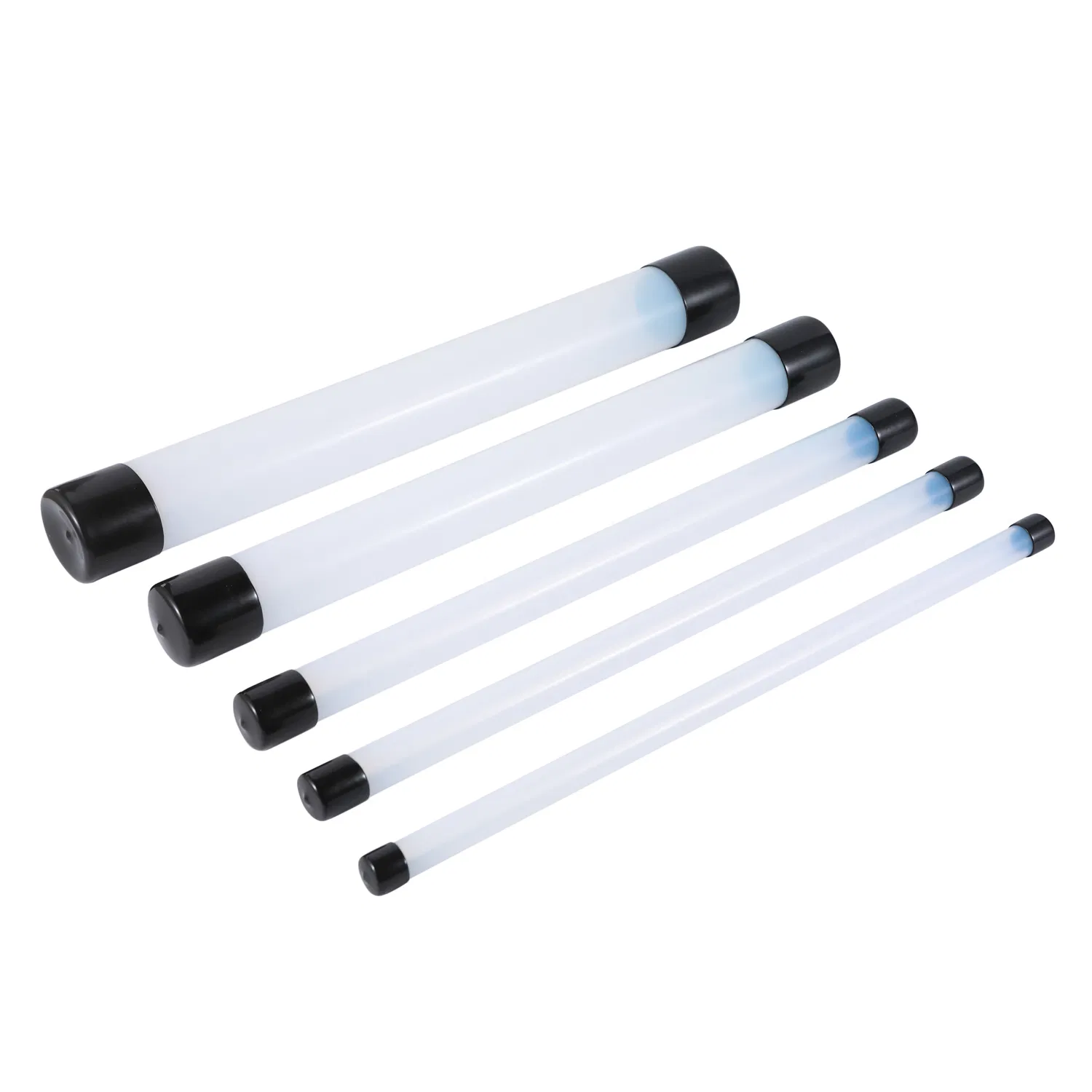

Polytetrafluoroethylene (PTFE) tubes are renowned for their versatility and resilience in various industrial applications. However, like all materials, PTFE is not immune to wear and tear. Understanding PTFE tube fatigue and knowing when to take action can help maintain optimal performance and extend the life of your tubing system.

PTFE tube fatigue refers to the gradual deterioration of the tube’s properties due to repeated stress and strain over time. This can manifest as cracks, discoloration, or a decline in flexibility. Recognizing these signs early can prevent further damage and costly replacements.

Signs of PTFE Tube Wear

Monitoring your PTFE tubes for specific signs of wear is crucial. Key indicators include:

- Cracking: Small cracks or splits on the surface suggest the tube is becoming brittle.

- Discoloration: Any change in color, particularly yellowing, can indicate chemical degradation.

- Reduced Flexibility: A noticeable stiffness or loss of flexibility can signal material fatigue.

- Leakage: The presence of leaks can be a sign of severe wear, and immediate action is needed.

Causes of PTFE Tube Deterioration

Understanding what leads to PTFE tube damage can help in preventive maintenance. Common causes include:

- Mechanical Stress: Repeated bending and movement can weaken the tube.

- Chemical Exposure: Harsh chemicals can accelerate the deterioration process.

- Temperature Extremes: Operating at temperatures outside the recommended range can affect the tube’s integrity.

- Aging: Over time, even with normal use, the material can naturally degrade.

Solutions for Maintaining PTFE Tubing

To ensure your PTFE tubing performs optimally, consider these maintenance strategies:

Regular Inspections

Conduct routine inspections to identify early signs of wear. This involves checking for surface damage, testing flexibility, and ensuring there are no leaks.

Controlled Environment

Maintain the tubes within the recommended temperature and pressure limits. Avoid exposure to chemicals that can damage PTFE.

Replacement Protocol

Establish a protocol for when to replace PTFE tubes. If you notice any of the wear signs mentioned earlier, consider replacing the tube to prevent system failures.

Proper Installation

Ensure that PTFE tubes are installed correctly to minimize unnecessary stress. Proper support and alignment can reduce mechanical strain.

When to Replace PTFE Tubes

Knowing when to replace PTFE tubes is crucial for maintaining system efficiency. Replace tubes if:

- There are visible cracks or leaks.

- The tube has lost significant flexibility.

- The tube has undergone significant discoloration.

By understanding and addressing PTFE tube fatigue, you can ensure the longevity and reliability of your tubing systems. Regular maintenance and timely replacements will help avoid unexpected downtimes and extend the life of your PTFE tubes.