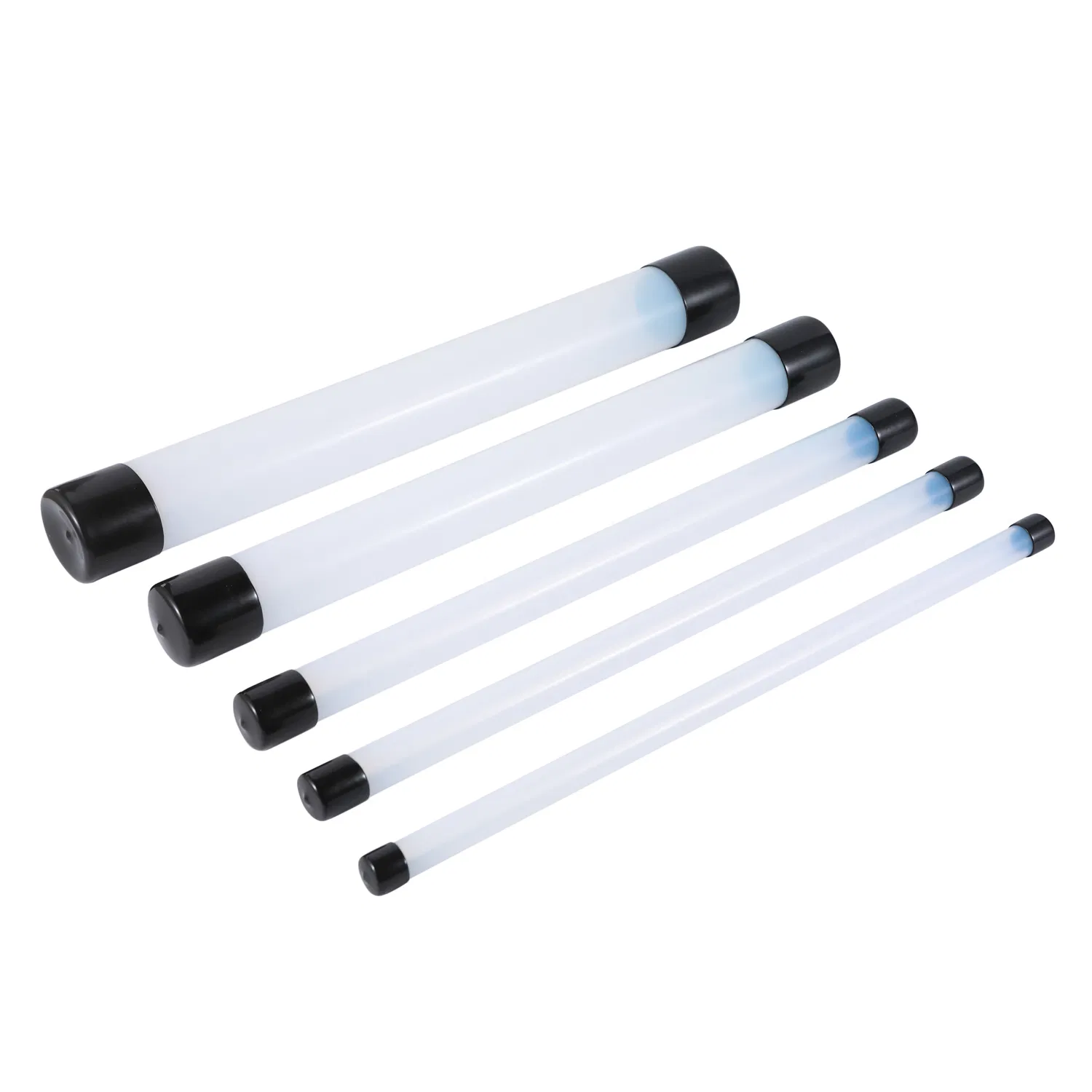

In the world of industrial applications, achieving a precise flush cut on PTFE Teflon tubes is vital for ensuring proper functionality and fit. PTFE, known for its non-stick properties and resistance to heat and chemicals, is widely used in various industries. Here, we will explore the essentials of PTFE Teflon tube flush cuts, offering insights and tips to ensure you get a clean and accurate cut every time.

A flush cut on a PTFE Teflon tube is crucial for maintaining the integrity and performance of the tube in its application. A clean cut ensures that there are no rough edges, which could lead to wear and tear or interfere with the tube’s function. Whether used in procesamiento químico, electronics, or food industries, precision in cutting these tubes is essential for safety and efficiency.

Choosing the right tool is the first step in achieving a perfect flush cut. Specialized cutting tools for PTFE tubing are designed to provide a smooth, clean cut without compressing or distorting the tube. Tools such as rotary cutters, precision saws, or even sharp utility knives can be used, depending on the thickness and diameter of the tube. Always ensure your cutting tool is sharp to avoid frayed edges.

Steps to Achieve a Clean Flush Cut

- Measure and Mark: Start by accurately measuring the length you need and marking it on the tube with a fine-tip marker. Precision in this step will help ensure the cut is where you need it to be.

- Secure the Tube: Use a vice or clamp to hold the PTFE tube steady. This prevents movement during the cutting process and helps achieve a more precise cut.

- Cut with Precision: Using your chosen tool, apply even pressure and cut along the marked line. For thick-walled tubes, a rotary cutter is often recommended for its ability to maintain uniformity.

- Inspect the Cut: After cutting, inspect the edge of the tube to ensure it is smooth and flush. Any roughness or unevenness can be sanded down gently with fine-grit sandpaper.

Tips for Optimal Results

- Keep Tools Sharp: Dull blades can cause jagged cuts and require more force, which can damage the tube.

- Practice Safety: Always wear safety glasses and gloves when cutting to protect yourself from any small debris or accidental slips.

- Test the Fit: Before finalizing, test the fit of the cut tube in its application to ensure it meets your requirements.

Conclusión

Mastering the art of flush cutting PTFE Teflon tubing can significantly enhance the performance and longevity of your projects. By selecting the right tools and following a methodical approach, you can achieve precision cuts that meet the high standards required in industrial applications. Remember, practice makes perfect, and with time, you will find the technique that works best for your specific needs.