In today’s demanding industrial landscape, the durability and reliability of materials used in manufacturing processes are crucial. One such material that has become indispensable is the 15% glass fiber-filled PTFE rod. These rods are designed to enhance the mechanical properties of standard PTFE, providing unmatched strength and durability. In this article, we will explore the benefits and applications of these advanced materials and why they are a must-have for industries seeking enhanced performance.

Understanding Glass Fiber PTFE Rods

Glass Fiber PTFE rods are composite materials that combine the properties of PTFE (Polytetrafluoroethylene) with glass fibers. PTFE, known for its non-stick properties and chemical resistance, is enhanced by the addition of glass fibers, which significantly improve its strength and durability. The standard composition includes 15% glass fiber, which strikes the right balance between strength and flexibility.

Composition and Production

The production of glass fiber PTFE rods involves an intricate process that ensures the even distribution of fibers throughout the PTFE matrix. This uniformity is crucial as it guarantees that the enhanced properties are consistent across the entire rod. By using state-of-the-art manufacturing techniques, producers can create rods that meet stringent industry standards. This uniform integration of glass fibers not only improves mechanical properties but also ensures that the rods perform reliably under varied conditions.

Enhanced Mechanical Properties

The integration of glass fibers into PTFE brings about a remarkable transformation in its mechanical properties. The tensile strength of these rods is significantly higher compared to standard PTFE, making them suitable for applications involving heavy loads. Furthermore, the glass fibers provide excellent resistance to deformation under stress, ensuring that the rods maintain their shape and functionality over time. This enhancement in mechanical properties makes them indispensable in high-stress environments.

Temperature and Chemical Resistance

Glass fiber PTFE rods are engineered to withstand extreme temperatures without losing their structural integrity. This resistance is vital for industries where thermal fluctuations are common. Similarly, these rods maintain the inherent chemical resistance of PTFE, protecting against a wide range of corrosive agents. This dual resistance—both thermal and chemical—ensures that the rods perform consistently, even in the most challenging conditions.

Advantages of 15% Glass Fiber Filled PTFE Rods

Improved Durability and Performance

The primary advantage of using 15% glass fiber-filled PTFE rods is their enhanced durability. The addition of glass fibers reduces wear and tear, extending the lifespan of components. This is particularly beneficial in applications where mechanical stress and high temperatures are common.

Long-term Cost Efficiency

While the initial cost of glass fiber PTFE rods may be higher than standard PTFE, the long-term benefits outweigh the investment. The extended lifespan and reduced maintenance costs lead to significant savings in the long run, making them a cost-effective choice for industries.

Versatility in Applications

These rods are incredibly versatile and can be used in a wide range of applications. From aerospace and automotive to chemical processing and food industries, the properties of glass fiber PTFE rods make them suitable for various environments.

Maintenance and Downtime Reduction

By opting for glass fiber PTFE rods, industries can significantly cut down on maintenance-related downtime. The enhanced durability means fewer replacements and repairs are necessary, allowing for smoother operations. This reduction in maintenance not only saves money but also boosts productivity by minimizing interruptions in the manufacturing process.

Applications of Glass Fiber PTFE Rods

Aerospace Industry

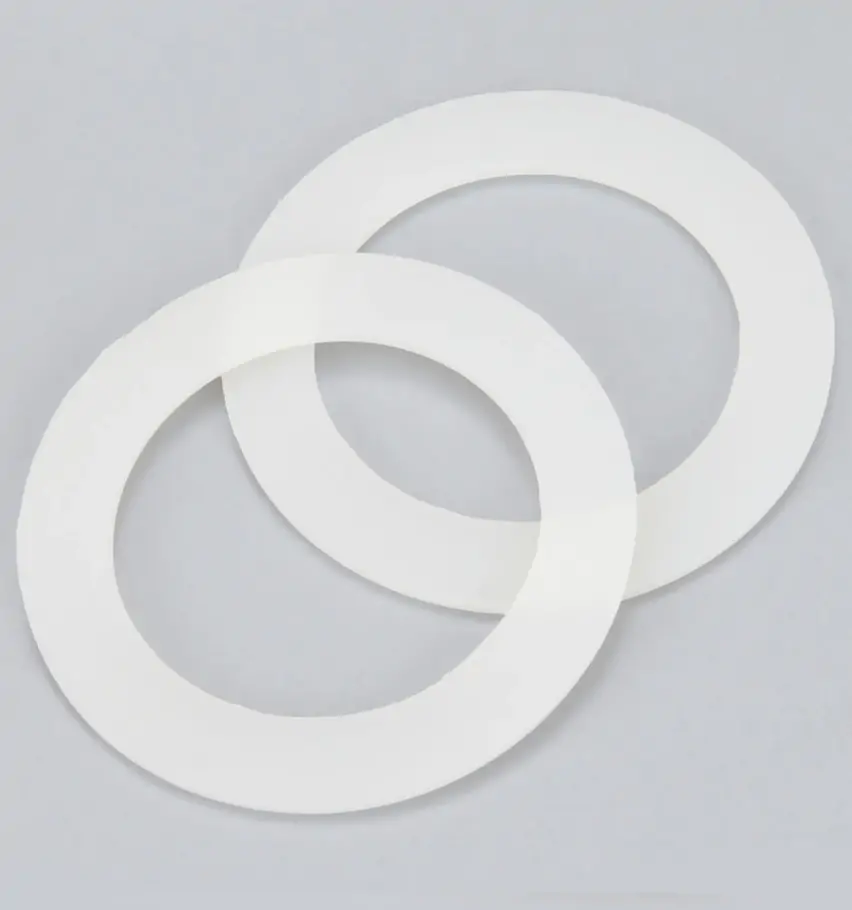

In the aerospace industry, where materials are subjected to extreme conditions, the durability and resistance of glass fiber PTFE rods are invaluable. They are often used in the manufacturing of seals, gaskets, and bearings that must endure high pressures and temperatures.

Automotive Industry

The automotive industry benefits from the low friction and high wear resistance of these rods. They are commonly used in the production of bushings, washers, and seals, contributing to the longevity and reliability of vehicle components.

Chemical Processing

In chemical processing plants, the resistance to corrosive substances makes glass fiber PTFE rods an ideal choice. They are used in the production of components like valve seats, pump parts, and pipe linings.

Food Industry

The food industry requires materials that are both durable and safe. Glass fiber PTFE rods meet these criteria and are used in various food processing equipment, ensuring compliance with safety standards while providing excellent performance.

Additional Industrial Applications

Beyond these core industries, glass fiber PTFE rods find applications in electronics, medical devices, and marine equipment. Their ability to withstand harsh environments and maintain performance makes them a preferred choice across diverse fields. Whether it’s insulating components in electronic devices or providing corrosion-resistant parts in marine settings, these rods deliver unparalleled reliability.

Choosing the Right Glass Fiber PTFE Rods

When selecting glass fiber PTFE rods, it is crucial to consider factors such as the specific application requirements, environmental conditions, and mechanical stress levels. Working with a reputable supplier ensures that you receive high-quality materials that meet industry standards.

Customization Options

Many manufacturers offer customization options for glass fiber PTFE rods, allowing you to tailor the material to your specific needs. Whether you require rods with different diameters, lengths, or additional properties, customization ensures optimal performance.

Supplier Credibility and Support

Choosing the right supplier involves more than just evaluating the product. It’s essential to assess the supplier’s credibility, industry experience, and customer support services. A reliable supplier provides technical support and guidance, helping you select the right specifications and ensuring seamless integration into your processes.

Quality Assurance and Testing

Before finalizing your choice, ensure that the rods meet rigorous quality assurance and testing standards. This step guarantees that the materials are free from defects and perform as expected in real-world applications. By prioritizing quality assurance, you can avoid potential failures and ensure the longevity of your components.

Conclusion

Glass fiber PTFE rods are a game-changer for industries that demand high-performance materials. Their durability, chemical resistance, and versatility make them an ideal choice for various applications. By investing in 15% glass fiber-filled PTFE rods, businesses can enhance the durability and efficiency of their operations, leading to long-term benefits and cost savings.

In conclusion, whether you are in the aerospace, automotive, chemical, or food industry, incorporating glass fiber PTFE rods into your processes can significantly boost the durability and reliability of your products. Choose these advanced materials to stay ahead in today’s competitive market. Investing in quality materials not only ensures operational excellence but also positions your business as a leader in innovation and reliability.