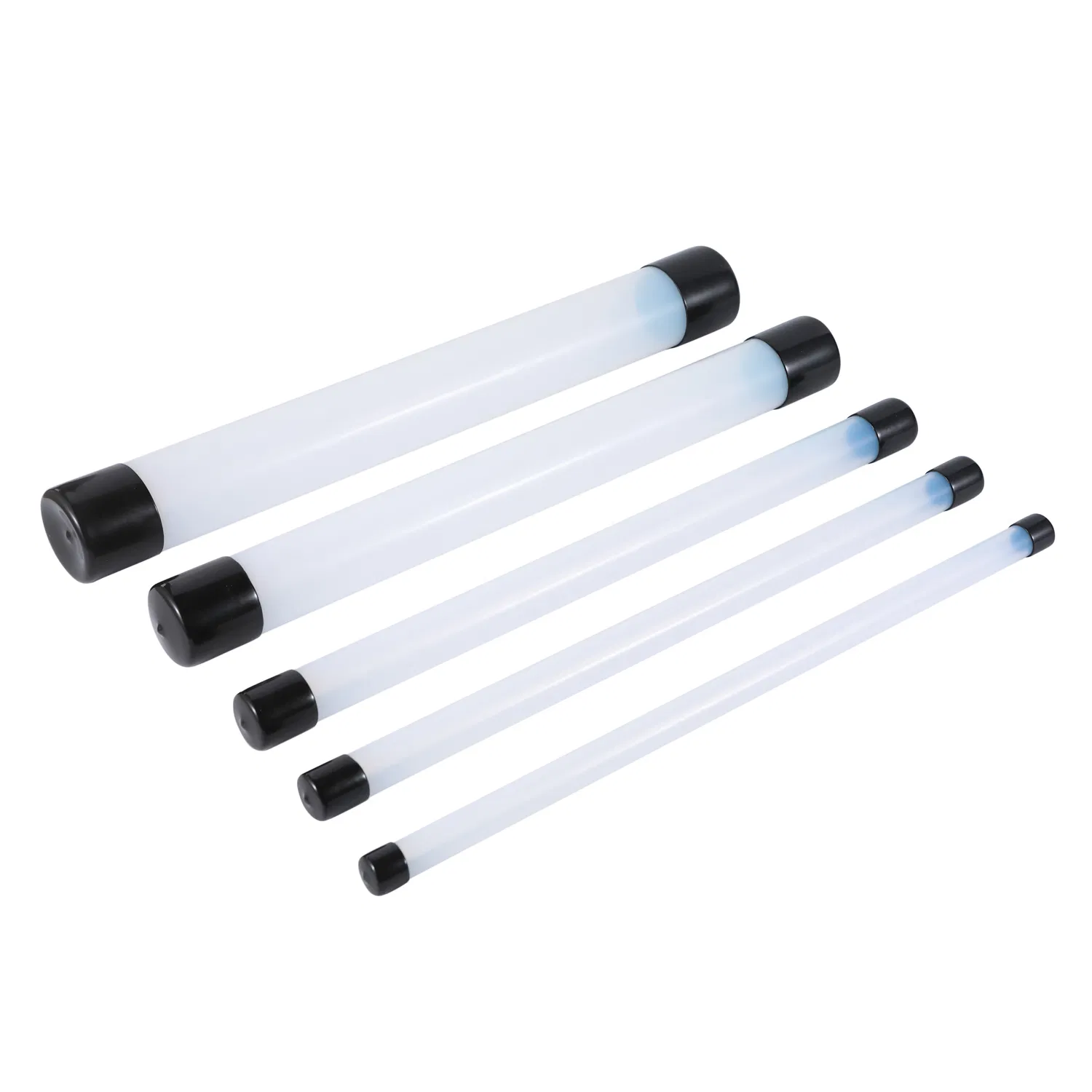

In various industries, the demand for materials that offer durability, flexibility, and resistance to harsh environments is ever-growing. Among the many materials available, PTFE (Polytetrafluoroethylene) stands out as a high-performance solution. In this article, we will explore the numerous advantages of using thin-wall PTFE tubes, which are commonly utilized in a wide range of applications.

What is PTFE?

PTFE, commonly known by the brand name Teflon, is a synthetic fluoropolymer of tetrafluoroethylene. It is renowned for its exceptional chemical resistance, low friction, and non-reactivity. These properties make PTFE an ideal choice for various industrial applications.

Key Properties of PTFE

- Chemical Resistance: PTFE is highly resistant to almost all chemicals, making it suitable for use in corrosive environments.

- Non-Stick Surface: Its low friction coefficient ensures a non-stick surface, preventing substances from adhering to it.

- Thermal Stability: PTFE can withstand extreme temperatures, ranging from -328°F to 500°F, without losing its properties.

- Electrical Insulation: PTFE has excellent insulating properties, which are beneficial for electrical applications.

Advantages of Thin-Wall PTFE Tubes

Lightweight and Flexible

Thin-wall PTFE tubes are incredibly lightweight and flexible, making them easy to handle and install in various applications. Their flexibility allows them to bend without breaking, which is essential in systems where space is limited or where there are frequent movements.

Chemical Resistance

One of the most significant advantages of thin-wall PTFE tubes is their exceptional chemical resistance. They can withstand exposure to a wide range of chemicals, including acids, bases, and solvents, without degrading. This makes them ideal for use in chemical processing industries.

High-Performance in Fluid Systems

Thin-wall PTFE tubes are often used in fluid systems due to their high-performance characteristics. They provide a reliable conduit for transporting fluids, including aggressive chemicals and gases, without the risk of contamination or reaction with the tubing material.

Thermal and Electrical Insulation

PTFE tubes offer excellent thermal insulation properties, making them suitable for high-temperature applications. Additionally, their electrical insulation capabilities make them a preferred choice in electrical and electronic applications where safety and reliability are paramount.

Non-Stick Surface

The non-stick surface of PTFE tubes is advantageous in applications where the build-up of residues or deposits is a concern. This property ensures a smooth flow of fluids and prevents clogging, which can be critical in maintaining the efficiency of fluid systems.

Applications of Thin-Wall PTFE Tubes

Chemical Processing

In chemical processing industries, PTFE tubes are used to transport aggressive chemicals safely. Their chemical resistance ensures that they do not react with the substances they carry, preventing contamination and ensuring the integrity of the process.

Medical and Pharmaceutical

In the medical and pharmaceutical fields, PTFE tubes are used for fluid transfer and as part of medical devices. Their biocompatibility and non-reactivity make them safe for use in contact with bodily fluids and sensitive drugs.

Automotive and Aerospace

In the automotive and aerospace industries, PTFE tubes are used for fuel lines, hydraulic systems, and lubrication systems. Their ability to withstand high temperatures and chemical exposure makes them suitable for these demanding applications.

Electrical and Electronics

PTFE tubes provide insulation for wiring and components in electrical and electronic devices. Their excellent dielectric properties ensure that they effectively prevent electrical leakage and protect sensitive components.

Comparing Thin-Wall PTFE Tubes to Other Materials

When compared to other materials like rubber, silicone, and PVC, thin-wall PTFE tubes offer superior performance in terms of chemical resistance, thermal stability, and durability. While rubber and silicone may offer flexibility, they cannot match the chemical resistance of PTFE. Similarly, PVC may provide cost-effectiveness, but it lacks the high-temperature resistance that PTFE offers.

Conclusion

Thin-wall PTFE tubes provide a versatile and high-performance solution for a variety of applications. Their unique properties, including chemical resistance, flexibility, and thermal stability, make them an invaluable asset in industries ranging from chemical processing to aerospace. By choosing PTFE tubes, businesses can ensure the longevity and efficiency of their systems, ultimately leading to cost savings and enhanced performance.

As you consider materials for your next project, keep in mind the advantages of thin-wall PTFE tubes. Their reliability and effectiveness are unmatched, making them a wise investment for any application requiring durable and resistant tubing.