In the world of industrial applications, choosing the right material for tubing is crucial. Rigid PTFE tubing stands out as a top choice for many due to its impressive properties and versatility. Whether you’re dealing with chemicals, high temperatures, or challenging environmental conditions, PTFE tubing proves to be a reliable solution. Here, we’ll explore the advantages of using rigid PTFE tubing in various industrial applications.

One of the most significant benefits of rigid PTFE tubing is its exceptional chemical resistance. This tubing can handle exposure to a wide range of aggressive chemicals without degrading or losing its integrity. From strong acids to solvents, PTFE tubing remains unaffected, making it ideal for industries such as chemical processing, pharmaceuticals, and food production.

High-Temperature Performance

Another key advantage of PTFE tubing is its ability to withstand extreme temperatures. Rigid PTFE tubes can perform effectively in temperatures ranging from -328°F to 500°F (-200°C to 260°C). This makes it an excellent choice for applications that require high-temperature resistance, such as in the automotive, aerospace, and electronics industries.

Durability and Longevity

Durability is a vital factor when selecting tubing for industrial purposes. PTFE rigid tubing is renowned for its long-lasting performance and ability to endure harsh environments. Its non-reactive nature and resistance to wear and tear ensure that it remains functional for extended periods, reducing the need for frequent replacements and maintenance.

Low Friction and Non-Stick Properties

PTFE tubing is known for its low friction coefficient, which means that fluids and materials can pass through it smoothly without sticking. This non-stick property is beneficial in applications where material build-up can cause blockages or contamination. Industries like food processing and medical equipment manufacturing often rely on PTFE tubing for this reason.

Versatile Applications

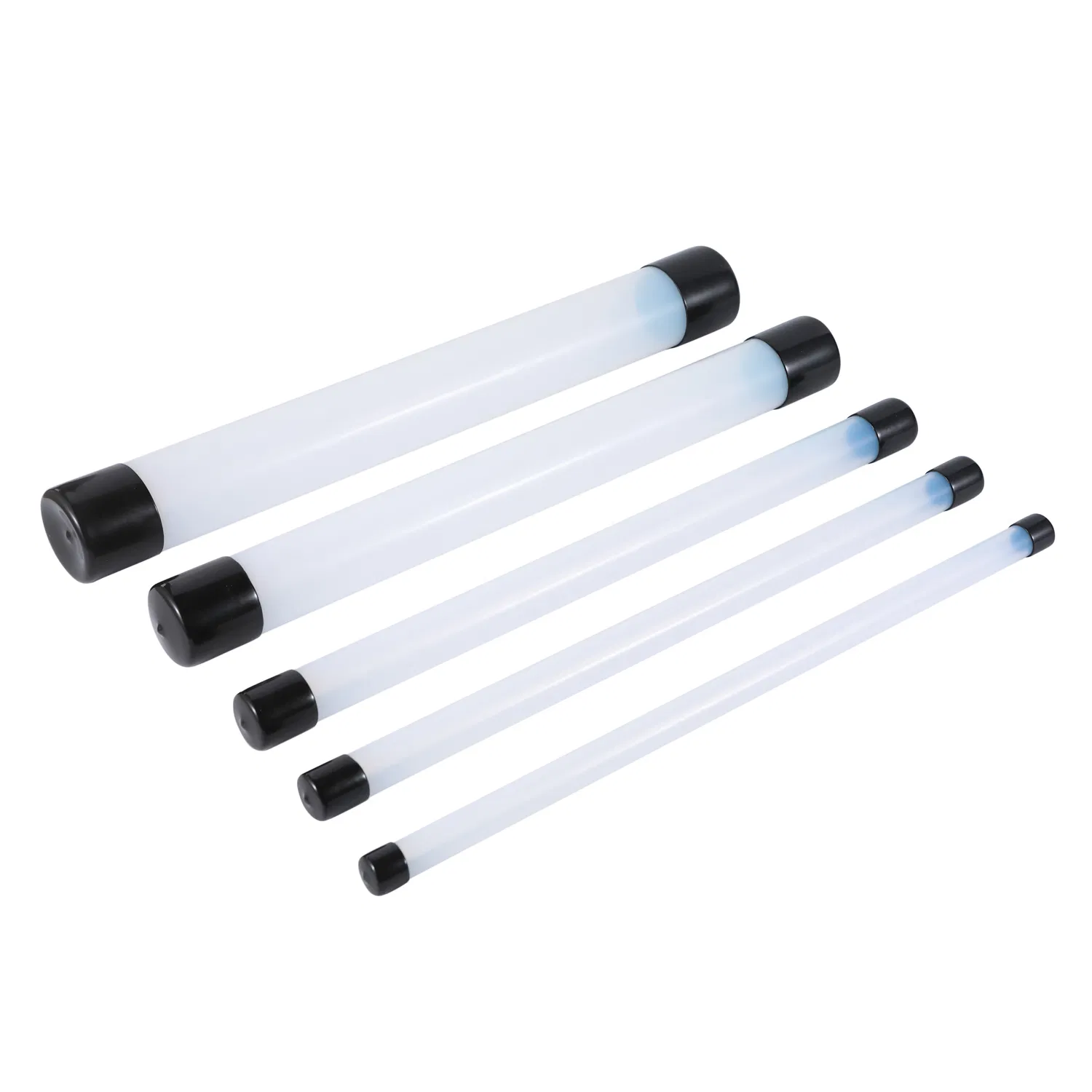

Rigid PTFE tubing is incredibly versatile, finding applications across a broad range of industries. Its ability to handle high pressures and resist environmental factors makes it suitable for use in fluid transfer systems, electrical insulation, and even as protective sleeving. Whether it’s a high-performance PTFE tube for challenging environments or a rigid Teflon tube for fluid conveyance, PTFE tubing offers a solution for many needs.

Conclusion

The advantages of using rigid PTFE tubing are clear: outstanding chemical resistance, high-temperature performance, durability, and versatile applications. When selecting tubing for industrial purposes, considering PTFE tubing can lead to significant long-term benefits and operational efficiency. By choosing PTFE, industries can ensure they have a reliable and high-performing material that meets their demanding requirements.

For those looking to leverage the benefits of PTFE tubing, understanding its unique properties and applications is key to maximizing its potential. Whether you need a chemical-resistant PTFE tube or a durable solution for fluid transport, PTFE tubing offers a high-performance option for various industrial needs.