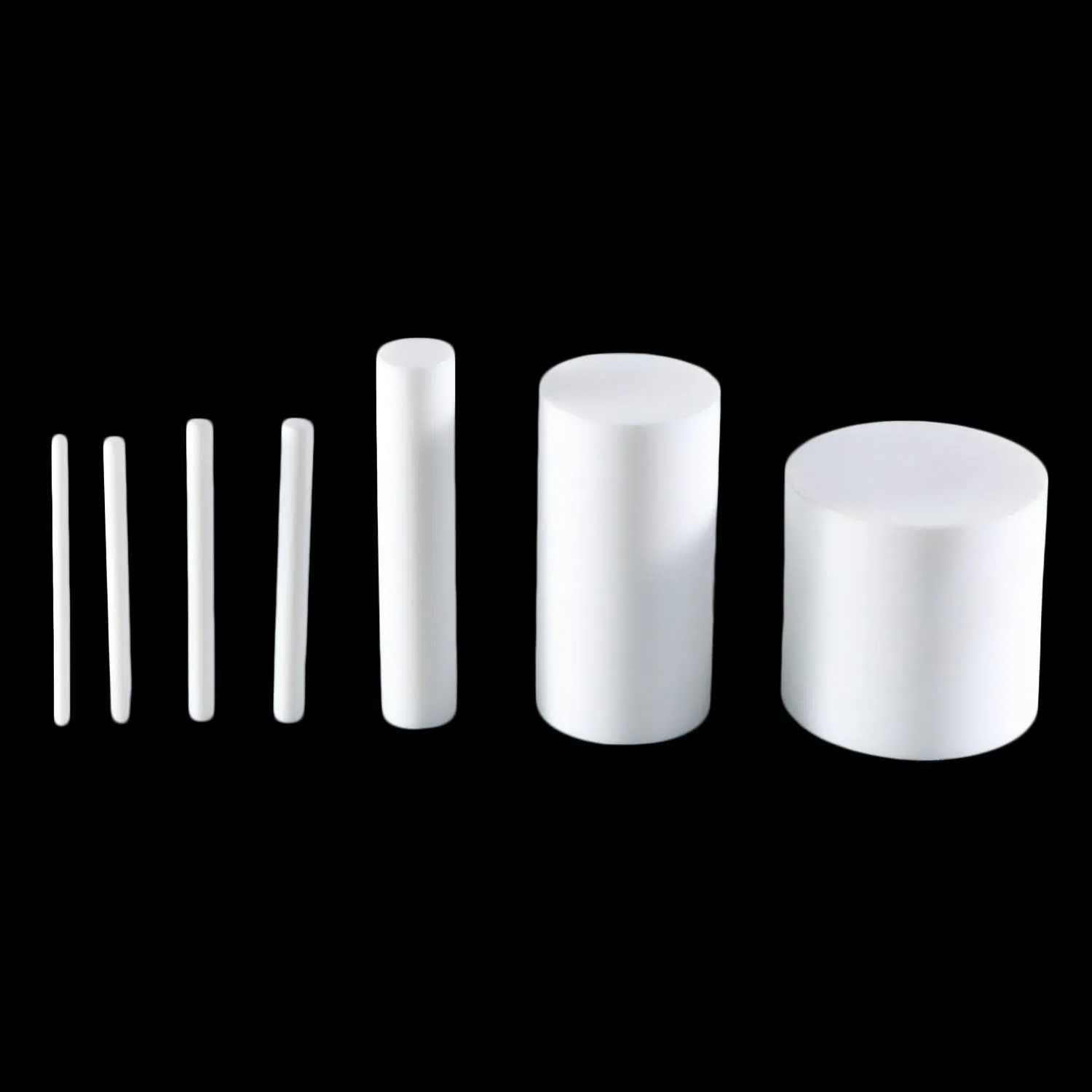

When it comes to industrial applications, choosing the right materials can significantly impact the efficiency and safety of operations. PTFE liner tubes stand out as an exceptional choice for many industries due to their unique properties and advantages. In this article, we will delve into the benefits of using PTFE liner tubes and why they might be the perfect solution for your needs.

PTFE, or polytetrafluoroethylene, is a synthetic fluoropolymer of tetrafluoroethylene. Its most well-known brand name is Teflon, which is often associated with non-stick cookware. However, PTFE’s uses extend far beyond the kitchen. It is widely used in industries such as chemical processing, electronics, and pharmaceuticals due to its remarkable properties.

Key Properties of PTFE

PTFE is renowned for its excellent chemical resistance, low friction, and high-temperature tolerance. These properties make it an ideal material for various industrial applications, especially when dealing with aggressive chemicals and extreme temperatures.

Benefits of Using PTFE Liner Tubes

Superior Chemical Resistance

One of the primary advantages of PTFE liner tubes is their exceptional chemical resistance. PTFE can withstand almost all corrosive substances, including acids, bases, and solvents. This makes PTFE-lined pipes and tubes particularly useful in industries where chemical exposure is frequent and intense.

High-Temperature Tolerance

PTFE can operate effectively in a wide temperature range, typically from -200°C to +260°C. This makes it suitable for applications involving high heat or extreme cold. Whether it’s in a cryogenic environment or a hot chemical process, PTFE liner tubes maintain their integrity and performance.

Low Friction and Non-Stick Surface

The low friction coefficient of PTFE means materials can flow smoothly through PTFE-lined pipes without sticking. This non-stick property reduces energy consumption and improves efficiency in fluid transport, making PTFE tubing an excellent choice for industries that handle sticky or viscous materials.

Electrical Insulation

PTFE is an outstanding electrical insulator, which makes it valuable in applications requiring reliable insulation at high frequencies and voltages. Its insulating properties are maintained across a wide temperature range, enhancing safety and performance in electrical applications.

Durability and Longevity

PTFE liner tubes are known for their durability and long service life. They resist wear and tear even under harsh conditions, reducing the need for frequent replacements. This longevity translates to cost savings and operational efficiency over time.

Applications of PTFE Liner Tubes

Chemical Processing Industry

In chemical processing plants, PTFE liner tubes are often used to transport aggressive chemicals. The tubes’ resistance to corrosion ensures that they can handle even the most reactive substances without degrading or contaminating the product.

Pharmaceutical Industry

PTFE tubes are also used in the pharmaceutical industry, where purity and cleanliness are crucial. The non-reactive nature of PTFE ensures that it does not interact with pharmaceutical compounds, maintaining the integrity of the products.

Food and Beverage Industry

In the food and beverage industry, PTFE’s non-stick and non-reactive properties are particularly beneficial. PTFE-lined pipes are used to transport food products without contamination, ensuring safety and quality.

Electronics Industry

PTFE’s excellent electrical insulation makes it a preferred choice in the electronics industry. It is used in wiring and components where reliable insulation is necessary, especially in high-frequency and high-voltage applications.

PTFE Liner Tubes vs. Other Liner Materials

Comparison with Steel Liner Tubes

Steel liner tubes are strong and durable but can be prone to corrosion when exposed to certain chemicals. PTFE liner tubes, in contrast, offer superior chemical resistance, making them a better choice for environments with corrosive substances.

Comparison with Other Plastics

While other plastics may offer some level of chemical resistance, PTFE stands out due to its combination of high temperature tolerance, low friction, and non-stick properties. This makes PTFE liner tubes more versatile and reliable in demanding applications.

Installation and Maintenance

Easy Installation

PTFE liner tubes are relatively easy to install. They can be custom-made to fit specific dimensions and configurations, simplifying the installation process. Additionally, their flexibility allows for easier handling and placement.

Low Maintenance Requirements

Once installed, PTFE liner tubes require minimal maintenance. Their resistance to corrosion and wear means they do not need frequent inspections or replacements, reducing downtime and maintenance costs.

Conclusion

PTFE liner tubes offer a range of advantages that make them an excellent choice for various industrial applications. From their superior chemical resistance and high-temperature tolerance to their low friction and non-stick properties, PTFE tubes provide reliable performance and long-term value. Whether in chemical processing, pharmaceuticals, food and beverage, or electronics, PTFE liner tubes can enhance efficiency, safety, and durability in your operations.

By choosing PTFE liner tubes, you invest in a solution that meets the demands of modern industry, ensuring that your processes run smoothly and effectively.