PTFE gaskets are essential components in many industrial applications. They offer excellent chemical resistance and low friction properties. These gaskets are known for their ability to operate in extreme temperatures, from -200°C to 260°C.

Understanding the mechanical properties of PTFE gaskets is crucial for optimal performance. These properties include high tensile strength and flexibility. However, PTFE gaskets can suffer from issues like creep and cold flow.

Proper installation and maintenance are key to preventing PTFE gasket failure. Selecting the right gasket for your application ensures longevity and efficiency. This guide will explore the mechanical properties and applications of PTFE gaskets.

What is a PTFE Gasket? Definition and Meaning

A PTFE gasket is a sealing product made from polytetrafluoroethylene. Known for its non-reactive nature, it resists chemicals and high temperatures.

These gaskets are invaluable in industries like pharmaceuticals and food processing. They provide safe and efficient sealing solutions. PTFE gaskets are commonly referred to as Teflon gaskets, a well-known brand.

Key features of PTFE gaskets include:

- High chemical resistance

- Broad temperature range

- Low friction surface

Key Mechanical Properties of PTFE Gaskets

PTFE gaskets boast exceptional mechanical properties. They are known for their strength and flexibility. This makes them ideal for various demanding applications.

One of the standout characteristics is high tensile strength. This allows PTFE gaskets to withstand substantial pressure without breaking. They also exhibit notable elongation at break.

Despite their strength, PTFE gaskets are incredibly flexible. Their low modulus of elasticity allows them to conform to uneven surfaces. This ensures a reliable seal in challenging conditions.

Another key property is their resistance to creep and cold flow. Although prone to some degree of deformation over time, well-designed PTFE gaskets maintain their integrity under pressure. Proper design can minimize these effects.

Key mechanical properties of PTFE gaskets include:

- High tensile strength

- Flexibility due to low modulus of elasticity

- Resistance to creep and cold flow

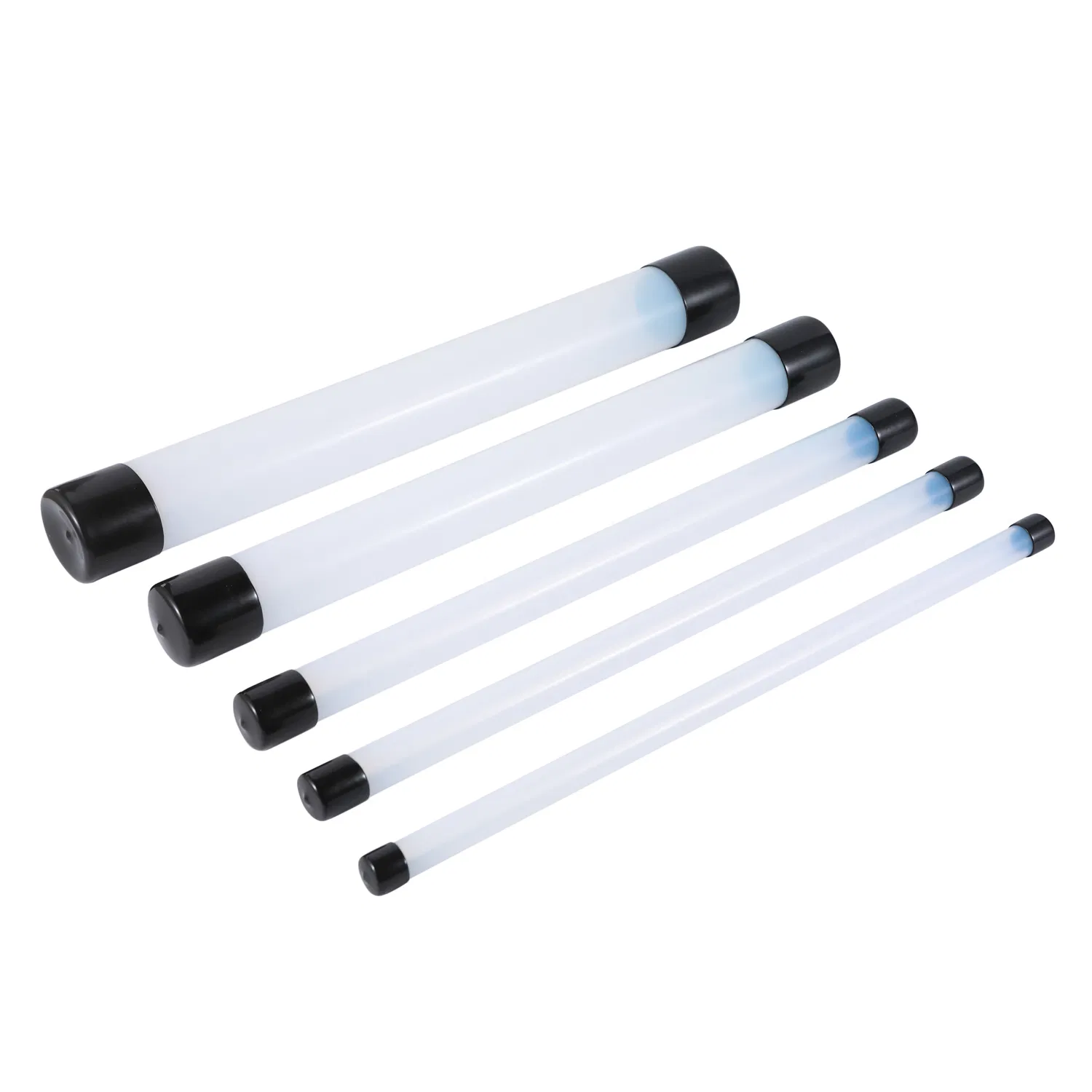

Types of PTFE Gaskets: Virgin, Filled, and Expanded

PTFE gaskets come in several varieties, each suited for specific needs. The three most common types are virgin, filled, and expanded PTFE.

Virgin PTFE gaskets are made from pure PTFE. They offer high chemical resistance and flexibility. However, their mechanical strength may be lower compared to other types.

Filled PTFE gaskets contain additives like glass or carbon. These fillers enhance mechanical properties. They provide improved strength and reduced creep, making them suitable for high-pressure applications.

Expanded PTFE gaskets are known for their enhanced flexibility. They can conform better to sealing surfaces. This makes them ideal for applications requiring tighter seals.

Key types of PTFE gaskets include:

- Virgin PTFE

- Filled PTFE

- Expanded PTFE

Choosing the right type depends on your specific application needs. It’s crucial to consider factors like pressure, temperature, and chemical exposure when selecting a PTFE gasket.

PTFE Gasket Temperature Limits and Pressure Ratings

PTFE gaskets are known for their wide temperature range. They can typically operate from -200°C to 260°C. This makes them suitable for both extreme cold and high heat applications.

Pressure ratings for PTFE gaskets vary. The exact rating depends on the specific gasket design and application environment. Always consult the PTFE gasket datasheet for precise pressure capabilities.

A key advantage of PTFE gaskets is their versatility. They can withstand harsh conditions, including high pressure and temperature. This adaptability makes them popular in industries like chemical processing and oil and gas.

When selecting PTFE gaskets, consider both temperature and pressure limits. Ensure compatibility with your application to prevent gasket failure.

PTFE gaskets should meet the following operational criteria:

- Temperature: -200°C to 260°C

- Suitable for high pressure

- Manufacturer’s pressure limits

Chemical Resistance and Material Compatibility

PTFE gaskets offer excellent chemical resistance. This makes them ideal for environments with harsh chemicals. They can resist acids, bases, and solvents.

Material compatibility is crucial for PTFE gaskets. Always ensure your gasket matches the materials it will contact. This prevents unwanted reactions and prolongs gasket life.

PTFE gaskets are often chosen for their versatility. They perform well across different industries. Here are key points to consider about their chemical and material properties:

- Resistant to corrosive substances

- Compatible with varied materials

- Suitable for aggressive environments

Each of these characteristics enhances PTFE’s appeal in diverse industrial applications, ensuring reliability and safety.

Common PTFE Gasket Defects and Failure Modes

Understanding common defects in PTFE gaskets is important. Surface imperfections can impact sealing performance significantly. Regular inspections help identify these issues early.

Manufacturing defects are another concern. These can lead to gasket failure during operation. It’s critical to source gaskets from reliable manufacturers to minimize this risk.

PTFE gaskets can also suffer from creep and cold flow. These issues arise under prolonged stress or temperature exposure. Proper selection based on application conditions can mitigate these failures.

Here is a list of common PTFE gasket defects and failure modes:

- Surface imperfections

- Manufacturing defects

- Creep and cold flow

By understanding these potential problems, users can take steps to prevent them. This ensures that gaskets deliver optimal performance and longevity in various applications. Regularly monitoring gaskets and choosing high-quality products can make a big difference in service life.

PTFE Gasket Creep, Cold Flow, and Surface Finish

PTFE gaskets are known for their flexibility but can suffer from creep. Over time, under constant load, gaskets may deform. This deformation is referred to as creep and could compromise sealing effectiveness.

Cold flow is another issue, especially at high pressures. Gaskets may extrude or change shape under severe conditions. Selecting the right type and design minimizes the risks of cold flow.

A smooth surface finish on PTFE gaskets is essential for effective sealing. Rough surfaces may create gaps, leading to leaks. Therefore, ensuring a flawless surface is key to maintaining gasket performance.

Considerations for PTFE gasket optimization:

- Monitor for signs of creep.

- Avoid cold flow with appropriate gasket choice.

- Ensure high-quality surface finishes.

Paying attention to these details increases gasket durability and reliability. Proper handling and installation can further enhance gasket performance across various applications.

PTFE Gasket Design Considerations and Selection Factors

Choosing the right PTFE gasket requires understanding specific application needs. Several factors determine the best design for optimal performance.

Consider the operating temperature and pressure first. PTFE gaskets must withstand these conditions without degrading. Analyzing these elements ensures the gasket remains effective over time.

Chemical compatibility is another key aspect. PTFE’s resistance to various chemicals enhances its suitability for diverse environments. Verify compatibility to prevent unexpected gasket deterioration.

Customization options can cater to unique requirements, providing flexibility in design. This includes choosing between shapes and sizes suitable for your application.

Key design considerations:

- Ensure compatibility with operating temperatures and pressures.

- Assess the chemical environment for potential reactions.

- Explore customization options for unique applications.

By focusing on these factors, you can select a PTFE gasket that provides maximum efficiency and reliability, extending the service life and performance of your installations.

Installation, Handling, and Sealing Tricks for PTFE Gaskets

Proper installation is crucial for PTFE gasket performance. Ensuring a perfect seal requires attention to detail during the setup process.

Avoid over-compressing the gasket. PTFE material can creep, leading to potential leakage over time. Using the correct torque settings is essential.

Handling PTFE gaskets gently prevents surface defects. Surface imperfections can impact the seal, reducing effectiveness and lifespan.

Sealing tricks include:

- Use even and controlled force when tightening.

- Ensure surfaces are clean and defect-free before installation.

- Avoid sharp edges that can damage the gasket.

By following these guidelines, you enhance the PTFE gasket’s sealing capabilities and longevity, ensuring reliable operation in various applications.

Applications and Industry Use Cases

PTFE gaskets excel across numerous industries due to their robustness and adaptability. Their chemical resistance is critical in environments with corrosive substances.

Industries that benefit significantly include:

- Chemical processing for handling aggressive chemicals.

- Food and beverage for hygienic sealing.

- Pharmaceuticals for contamination-free environments.

In automotive and aerospace sectors, PTFE gaskets are crucial for their thermal stability and low friction properties. Additionally, their utility extends to duct systems, ensuring efficient airflow and minimizing leaks. This wide range of applications underscores the versatility and reliability of PTFE gaskets in demanding industry settings.

How to Read a PTFE Gasket Data Sheet

Understanding a PTFE gasket data sheet is essential for selecting the right product. It details important technical specifications, ensuring you make an informed decision.

Key points to look for include:

- Temperature range

- Pressure rating

- Chemical compatibility

- Mechanical properties

These elements guide you in choosing a PTFE gasket that perfectly matches the application’s requirements, ultimately enhancing performance and reliability. Always refer to the data sheet to ensure compatibility and safety in your specific use case.

Sourcing High Quality PTFE Gaskets: What to Look For

Sourcing high quality PTFE gaskets involves careful evaluation of several critical factors. Always ensure manufacturers adhere to strict quality standards and industry certifications for reliability.

Consider these key factors when selecting:

- Material purity and consistency

- Manufacturer’s reputation

- Compliance with industry standards

- Customization options for specific needs

Relying on well-established factories ensures that the gaskets will perform under the toughest conditions. By focusing on these aspects, you can confidently source gaskets that will meet demanding industrial applications and last over time.

Conclusion: Maximizing PTFE Gasket Performance

Understanding the mechanical properties of PTFE gaskets helps maximize their performance and longevity. Selecting appropriate types and ensuring proper installation reduces failure risks.

By considering temperature, pressure, and chemical exposure, you can enhance gasket efficiency. Regular maintenance and storage in recommended conditions further ensure optimal operation, thus extending gasket life significantly.